Amalungu esinyithi achanekileyo ahlala eveliswa kusetyenziswa ubugcisa obahlukeneyo bokuchaneka, kunye nomatshini we-CNC uyindlela eqhelekileyo. Ngokwesiqhelo, iindawo ezichanekileyo zifuna imigangatho ephezulu yazo zombini imilinganiselo kunye nenkangeleko.

Ke ngoko, xa usebenzisa i-CNC machining metals ezifana ne-aluminium kunye nobhedu, ukwenzeka kwamanqaku esixhobo kunye nemigca kumphezulu wemveliso egqityiweyo kuyinkxalabo. Eli nqaku lixubusha izizathu ezibangela iimpawu zesixhobo kunye nemigca ngexesha lokwenziwa kweemveliso zetsimbi. Sikwacebisa izisombululo ezinokubakho.

Ukungonelanga ukuBamba amandla okuLungisa

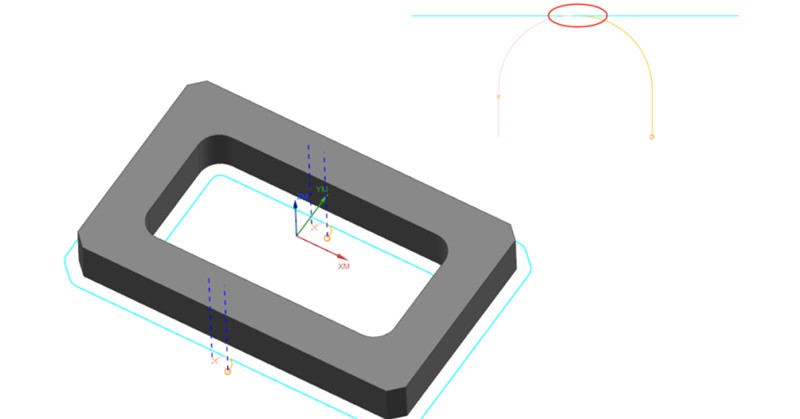

Oonobangela:Ezinye iimveliso zentsimbi yomngxunya kufuneka zisebenzise izixhobo zokufunxa, kwaye zinokusokola ukuvelisa ukufunxa okwaneleyo ngenxa yobukho bezitenxo zomphezulu, okukhokelela kumanqaku esixhobo okanye imigca.

Isisombululo:Ukunciphisa oku, qwalasela utshintsho ukusuka kwi-vacuum yokufunxa elula ukuya kwi-vacuum yokufunxa edityaniswe noxinzelelo okanye inkxaso esecaleni. Kungenjalo, jonga ezinye iindlela zokulungisa ezisekelwe kulwakhiwo lwamacandelo athile, ulungelelanisa isisombululo kwingxaki ethile.

Imiba eNxulumene neNkqubo

Oonobangela:Iinkqubo ezithile zokwenziwa kwemveliso zinokufaka isandla kulo mba. Umzekelo, iimveliso ezinjengeegobolondo zangasemva zePC zihamba ngokulandelelana kwamanyathelo omatshini abandakanya ukugqobhoza kwemingxuma esecaleni elandelwa yi-CNC yokugaya imiphetho. Olu landelelwano lunokukhokelela kumanqaku abonakalayo esixhobo xa ukugaya kufikelela kwiindawo ezisecaleni komngxuma.

Isisombululo:Umzekelo oqhelekileyo wale ngxaki uyenzeka xa i-alloy ye-aluminiyam ikhethwa kwiigobolondo zemveliso ye-elektroniki. Ukuyicombulula, inkqubo inokuguqulwa ngokutshintsha umngxuma osecaleni wokugaya kunye nokusila nge-CNC yokusila kuphela. Kwangaxeshanye, ukuqinisekisa ukusebenzisana kwesixhobo esingaguqukiyo kunye nokunciphisa ukusika okungalinganiyo xa kusila.

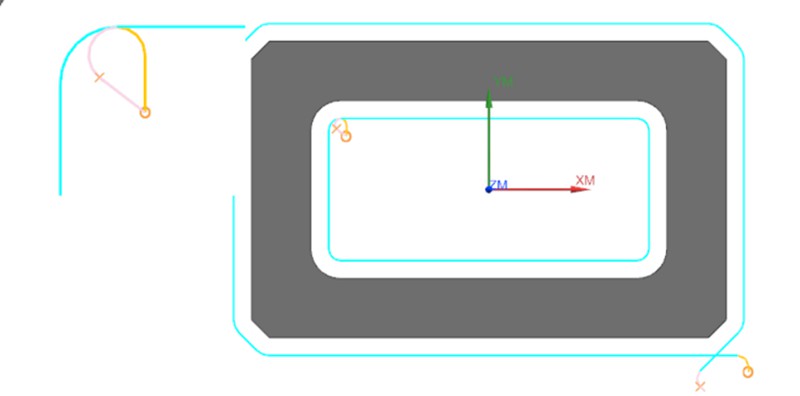

Ukungonelanga kweNkqubo yeNdlela yeNdlela yokuSebenza

Oonobangela:Lo mbandela udla ngokuvela ngexesha le-2D contour machining isigaba sokuveliswa kwemveliso. Ukubandakanyeka kwendlela yesixhobo eyenziwe kakubi kwiprogram ye-CNC, ukushiya umkhondo kwiindawo zokungena kunye nokuphuma kwesixhobo.

Isisombululo:Ukujongana nomceli mngeni wokuphepha amanqaku esixhobo kwiindawo zokungena kunye nokuphuma, indlela eqhelekileyo ibandakanya ukwazisa ukugqithelana okuncinci kumgama wokubandakanya isixhobo (malunga ne-0.2mm). Obu buchule busebenza ekuthinteleni izinto ezingachanekanga ekuchanekeni kwesikrufu sokukhokela sikamatshini.

Ngelixa esi sicwangciso sithintela ngokufanelekileyo ukubunjwa kwamanqaku esixhobo, kubangela into yokuphindaphinda ukuphindaphinda xa izinto zemveliso ziyintsimbi ethambileyo. Ngenxa yoko, eli candelo lingabonisa ukuguquguquka kokwakheka kunye nombala xa kuthelekiswa nezinye iindawo.

Iipateni zesikali seentlanzi kwiMigangatho yoomatshini abacaba

Oonobangela:Isikali sentlanzi okanye iipateni ezijikelezayo ezibonakala kumphezulu osicaba wemveliso. Izixhobo zokusika ezisetyenziselwa ukusetyenzwa kweentsimbi ezithambileyo ezifana ne-aluminium / ubhedu ngokuqhelekileyo ziyi-alloy material mill kunye ne-3 ukuya kwi-4 flutes. Banobunzima obususela kwi-HRC55 ukuya kwi-HRC65. Ezi zixhobo zokusika zenziwa kusetyenziswa umgca ongezantsi wesixhobo, kwaye inxalenye yomhlaba inokuphuhlisa iipateni zesikali seentlanzi, ezichaphazela inkangeleko yayo yonke.

Isisombululo:Ngokuqhelekileyo ijongwa kwiimveliso ezineemfuno zokunyuka eziphezulu kunye nemigangatho ethe tyaba enezakhiwo ezihlaziyiweyo. Iyeza kukutshintshela kwizixhobo zokusika ezenziwe ngezinto zedayimani zokwenziwa, ezinceda ukufezekisa ukugqitywa komphezulu ogudileyo.

Ukuguga kunye nokuNxitywa kweZixhobo zeMixholo

Oonobangela:Uphawu lwezixhobo kumphezulu wemveliso lubangelwa kukwaluphala kunye nokuguga kwesixhobo sokusonta, iibheringi kunye nesikrufu selothe. Ukongeza, ukungonelanga kweeparamitha zokubuyela umva kwenkqubo ye-CNC kunegalelo kumanqaku esixhobo achaziweyo, ngakumbi xa kusenziwa iikona ezingqukuva.

Isisombululo:Le miba isuka kwimiba enxulumene nezixhobo kwaye inokuqwalaselwa ngogcino olujolisiweyo kunye nokutshintshwa.

Ukuqukumbela

Ukufikelela kwindawo efanelekileyo kwi-CNC machining metals kufuna iindlela eziluncedo. Kukho iindlela ezahlukeneyo zokuphepha iimpawu zesixhobo kunye nemigca ebandakanya indibaniselwano yokugcinwa kwezixhobo, ukuphuculwa kwezixhobo, ukulungiswa kwenkqubo, kunye nokulungiswa kweprogram. Ngokuqonda kunye nokulungisa le miba, abavelisi banokuqinisekisa ukuba izinto ezichanekileyo azifikeleli nje kuphela iinqobo zokulinganisa kodwa zikwabonisa iimpawu zobuhle ezinqwenelekayo.