Amalungu amaqokobhe amakhulu, abhityileyo anodonga kulula ukuwajika kwaye agqwetheke ngexesha lomatshini. Kweli nqaku, siza kwazisa i-heat sink case of the big and thin-walled-wall parts ukuze sixoxe ngeengxaki kwinkqubo yomatshini eqhelekileyo. Ukongeza, sikwabonelela ngenkqubo ephuculweyo kunye nesisombululo sokulungiswa. Masifikelele kuyo!

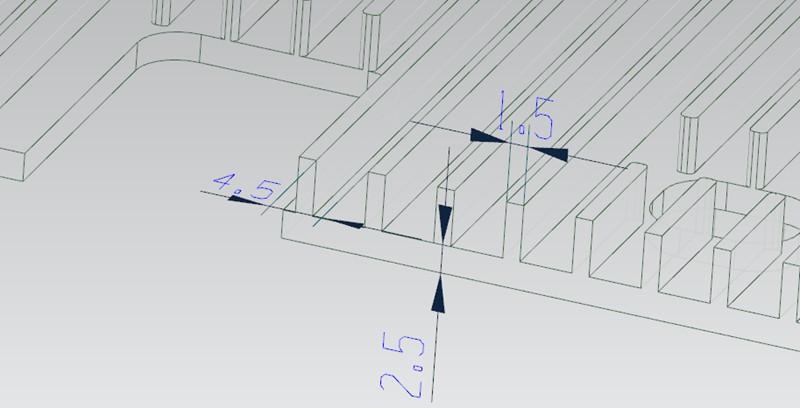

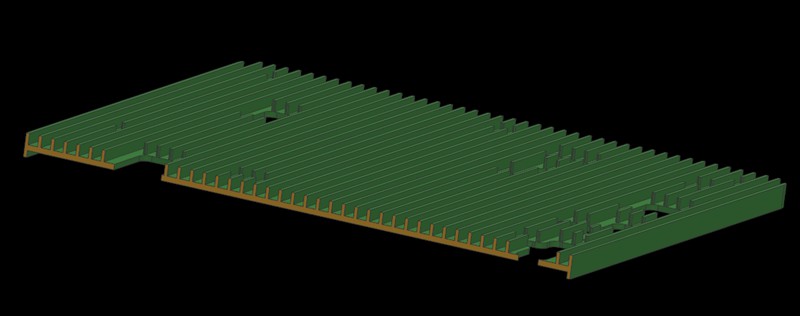

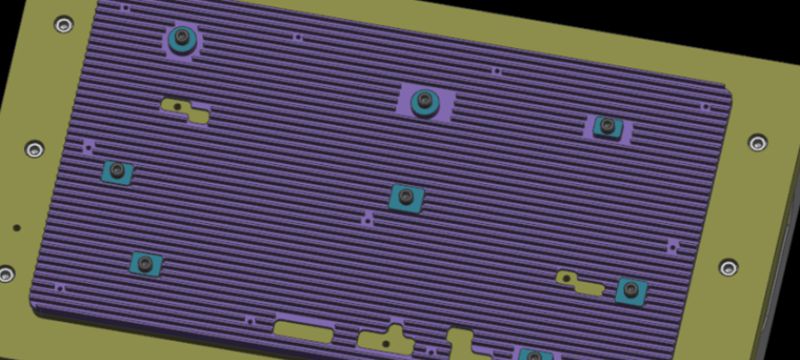

Ityala limalunga nenxalenye yeqokobhe eyenziwe ngezinto ze-AL6061-T6. Nantsi imilinganiselo yayo ngqo.

Ubungakanani bubonke: 455 * 261.5 * 12.5mm

Inkxaso yoDonga lokutyeba: 2.5mm

Ukutyeba kweSinki yobushushu: 1.5mm

Isithuba seSinki yoBubushushu: 4.5mm

Ukuziqhelanisa kunye nemingeni kwiindlela ezahlukeneyo zeNkqubo

Ngexesha le-CNC machining, ezi zakhiwo zeqokobhe ezibhityileyo zihlala zibangela uluhlu lweengxaki, ezinje nge-warping kunye nokuguqulwa. Ukoyisa le miba, sizama ukunika iinketho zenkqubo ye-serval. Nangona kunjalo, kusekho imiba ethile yenkqubo nganye. Nazi iinkcukacha.

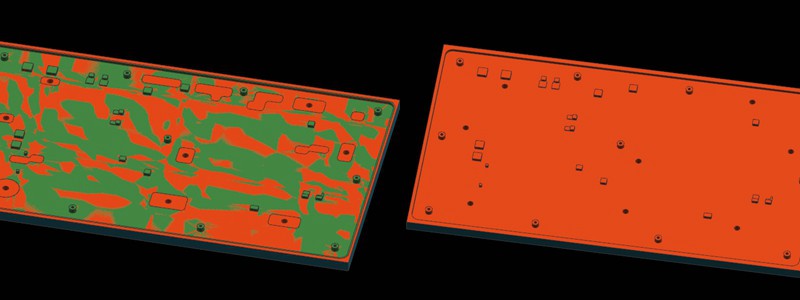

Indlela yeNkqubo 1

Kwinkqubo yoku-1, siqala ngokucwangcisa i-reverse side (icala langaphakathi) le-workpiece kwaye sisebenzise i-plaster ukuze sizalise iindawo ezivulekileyo. Emva koko, ukuvumela ukuba icala elingasemva libe yireferensi, sisebenzisa i-glue kunye ne-tape ephindwe kabini ukulungisa i-reference side endaweni ukwenzela ukuba umatshini wecala langaphambili.

Nangona kunjalo, kukho ezinye iingxaki ngale ndlela. Ngenxa yendawo enkulu egcwele i-backfilled kwicala elingasemva, iglue kunye ne-tape enamacala amabini ayikhuselekanga ngokwaneleyo i-workpiece. Ikhokelela ekulweni phakathi kwendawo yokusebenza kunye nokususwa kwezinto ezininzi kwinkqubo (ebizwa ngokuba yi-overcutting). Ukongeza, ukungabikho kozinzo lwe-workpiece kukhokelela ekusebenzeni okuphantsi kokusebenza kunye nepateni yemela embi.

Indlela yeNkqubo yesi-2

Kwinkqubo yesi-2, sitshintsha umyalelo womatshini. Siqala nge-underside (icala apho ubushushu buchithwa khona) kwaye sisebenzise i-backfilling ye-plaster yendawo engenanto. Emva koko, sivumela icala langaphambili njengesalathiso, sisebenzisa iglue kunye ne-tape ephindwe kabini ukulungisa icala lesalathiso ukuze sisebenze kwicala elingasemva.

Nangona kunjalo, ingxaki ngale nkqubo ifana nendlela yoku-1, ngaphandle kokuba umba utshintshelwe kwicala elingasemva (icala langaphakathi). Kwakhona, xa icala elingasemva linendawo enkulu yokubuyisela i-backfill, ukusetyenziswa kweglue kunye ne-tape enamacala amabini akunikezi uzinzo oluphezulu kwi-workpiece, okukhokelela ekulwa.

Indlela yeNkqubo 3

Kwinkqubo yesi-3, sicinga ukusebenzisa ukulandelelana kwe-machining yenkqubo 1 okanye inkqubo 2. Emva koko kwinkqubo yesibini yokuqinisa, sebenzisa ipleyiti yokushicilela ukubamba i-workpiece ngokucinezela phantsi kwi-perimeter.

Nangona kunjalo, ngenxa yendawo enkulu yemveliso, i-platen iyakwazi ukugubungela indawo yomjikelezo kwaye ayikwazanga ukulungisa ngokupheleleyo indawo ephakathi kwendawo yokusebenza.

Ngakolunye uhlangothi, oku kubangela indawo ephakathi kwendawo yokusebenza isabonakala ukusuka kwi-warping kunye nokuguqulwa, okukhokelela ekugqithiseni kwindawo ephakathi kwemveliso. Kwelinye icala, le ndlela yomatshini iya kwenza iqokobhe le-CNC elibhityileyo libe buthathaka kakhulu.

Indlela yeNkqubo 4

Kwinkqubo yesi-4, sisebenza ngomatshini kwicala elingasemva (icala langaphakathi) kuqala kwaye emva koko sisebenzise i-vacuum chuck ukuncamathisela inqwelomoya eyenziwe ngomatshini ukuze isebenze kwicala langaphambili.

Nangona kunjalo, kwimeko yenxalenye yeqokobhe elibhityileyo, kukho i-concave kunye ne-convex yezakhiwo kwicala elingasemva le-workpiece ekufuneka siyiphephe xa sisebenzisa i-vacuum fuction. Kodwa oku kuya kudala ingxaki entsha, iindawo ezithintelweyo zilahlekelwa amandla azo okufunxa, ngakumbi kwiindawo ezine zekona kwi-circumference yeprofayili enkulu.

Njengoko ezi ndawo zingaxutywanga zihambelana necala langaphambili (umhlaba owenziwe ngomatshini kule ndawo), i-bounce yesixhobo sokusika inokuthi yenzeke, ibangele iphethini yesixhobo sokungcangcazela. Ngoko ke, le ndlela ingaba nefuthe elibi kumgangatho we-machining kunye nokugqitywa komphezulu.

Indlela Yenkqubo Elungiselelweyo kunye nesisombululo sokuLungisa

Ukuze kusonjululwe ezi ngxaki zingentla, sicebisa le nkqubo ilandelayo yolondisiweyo kunye nezisombululo zokulungisa.

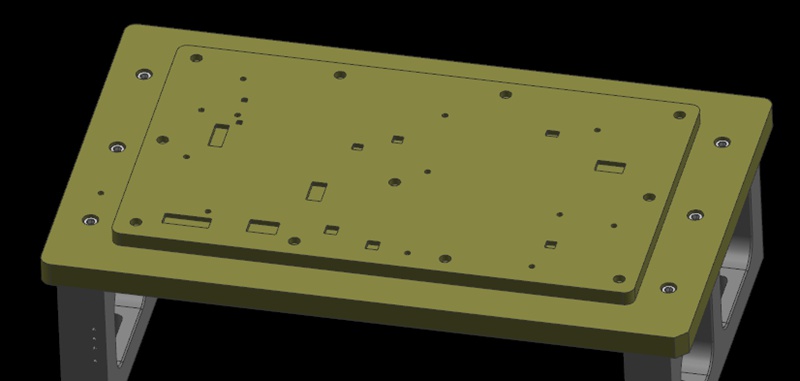

Pre-machining Screw Through-mingxuma

Okokuqala, siphucule indlela yenkqubo. Ngesisombululo esitsha, sicubungula icala elingasemva (icala langaphakathi) kuqala kunye nomatshini wangaphambi komatshini wokutyhutyha umngxuma kwezinye iindawo eziya kuthi ekugqibeleni zikhutshelwe ngaphandle. Injongo yale nto kukubonelela ngendlela engcono yokulungisa kunye nokubeka indawo kumanyathelo omatshini alandelayo.

Yenza isangqa kwiNdawo eza kwenziwa ngoMatshini

Emva koko, sisebenzisa iinqwelomoya ezenziwe ngomatshini kwicala elingasemva (icala langaphakathi) njengesalathiso somatshini. Kwangaxeshanye, sikhusela i-workpiece ngokudlula i-screw kwi-over-hole ukusuka kwinkqubo yangaphambili kwaye siyitshixe kwi-fixture plate. Emva koko ujikeleze indawo apho i-screw itshixiwe njengendawo yokwenziwa ngoomatshini.

Ukucwangcisa ngokulandelelanayo kunye nePlaten

Ngexesha lenkqubo yomatshini, siqala siqhubela phambili iindawo ngaphandle kwendawo eza kwenziwa ngoomatshini. Emva kokuba ezi ndawo zenziwe ngoomatshini, sibeka i-platen kwindawo yomatshini (i-platen idinga ukugqunywa ngeglue ukukhusela ukutyunyuzwa komgangatho owenziweyo). Emva koko sisusa i-screws esetyenziswe kwisinyathelo sesi-2 kwaye siqhubeke silungisa iindawo eziza kwenziwa ngoomatshini de yonke imveliso igqitywe.

Ngale nkqubo ilungiselelweyo kunye nesisombululo sokulungiswa, sinokubamba iqokobhe elibhityileyo le-CNC ngcono kwaye sinqande iingxaki ezinje nge-warping, ukonakala, kunye nokugawula ngaphezulu. I-screws ephakanyisiweyo ivumela i-plate yokulungisa ukuba ifakwe ngokuqinileyo kwi-workpiece, inika indawo ethembekileyo kunye nenkxaso. Ukongeza, ukusetyenziswa kwepleyiti yokucofa ukufaka uxinzelelo kwindawo yomatshini kunceda ukugcina i-workpiece izinzile.

Uhlalutyo olunzulu: Indlela yokuNqanda i-Warping kunye noTshintsho?

Ukufezekisa ubugcisa obunempumelelo bezakhiwo ezinkulu kunye nezibhityileyo zeqokobhe zifuna uhlalutyo lweengxaki ezithile kwinkqubo yomatshini. Makhe sihlolisise ngakumbi indlela le mingeni enokoyiswa ngayo ngempumelelo.

Pre-machining Side Ngaphakathi

Kwinqanaba lokuqala lomatshini (ukulungisa icala langaphakathi), izinto eziphathekayo ziyisiqwenga esiqinileyo esinamandla amakhulu. Ke ngoko, i-workpiece ayikhathazwa kukudityaniswa komatshini okufana ne-deformation kunye ne-warping ngexesha lale nkqubo. Oku kuqinisekisa ukuzinza kunye nokuchaneka xa usenza i-clamp yokuqala.

Sebenzisa iNdlela yokuTshixa kunye nokuCofa

Kwinqanaba lesibini (umatshini apho i-heat sink ikhona), sisebenzisa indlela yokutshixa kunye nokucinezela ukudibanisa. Oku kuqinisekisa ukuba i-clamping force iphezulu kwaye isasazwe ngokulinganayo kwinqwelo-moya exhasayo. Le clamping yenza imveliso izinzile kwaye ayijiki ngexesha lenkqubo yonke.

Esinye isisombululo: Ngaphandle koLwakhiwo oluHoli

Nangona kunjalo, ngamanye amaxesha sidibana neemeko apho kungenakwenzeka ukwenza isikrufu ngomngxuma ngaphandle kwesakhiwo esingenanto. Nasi esinye isisombululo.

Siyakwazi ukuyila kwangaphambili ezinye iintsika ngexesha lomatshini wecala elingasemva kwaye ucofe kuzo. Ngexesha lenkqubo elandelayo yomatshini, sine-screw yokudlula kwicala elingasemva le-fixture kwaye sitshixe i-workpiece, kwaye emva koko siqhube ukucwangciswa kwendiza yesibini (icala apho ubushushu buchithwa khona). Ngale ndlela, sinokugqiba inyathelo lesibini lomatshini kwipasi enye ngaphandle kokutshintsha ipleyiti embindini. Ekugqibeleni, songeza inyathelo lokuqhawula kathathu kwaye sisuse iintsika zenkqubo ukugqiba inkqubo.

Ukuqukumbela, ngokulungiselela inkqubo kunye nesisombululo sokulungiswa, sinokuyicombulula ngempumelelo ingxaki yokulwa kunye nokuguqulwa kwamalungu amakhulu, amancinci amancinci ngexesha lomatshini we-CNC. Oku akuqinisekisi kuphela umgangatho womatshini kunye nokusebenza kakuhle kodwa kuphucula ukuzinza kunye nomgangatho ophezulu wemveliso.