Ubuchwephesha be-CNC ngokungathandabuzekiyo bubomi boshishino lwemveliso kunye nezicelo ezifana ne-aerospace, izixhobo zonyango, kunye nombane. Kwiminyaka yakutshanje, kuye kwakho inkqubela phambili engakholelekiyo kwicandelo lezixhobo zomatshini ze-CNC. Ipotfoliyo yabo ebanzi ngoku ibonelela ngendibaniselwano enkulu yezinto eziphathekayo, iindleko, kunye nobuhle.

Kweli nqaku, siza kungena kwihlabathi elihlukeneyo lezinto ze-CNC. Siza kukubonelela ngesikhokelo esibanzi sokukhetha izixhobo ezifanelekileyo zeCNC machining, kubandakanya noluhlu oluneenkcukacha lwezixhobo ezisetyenziswa ngokuqhelekileyo. Ukongeza, siza kuchukumisa ezinye izixhobo ezingaziwayo onokuthi awuzange uziqwalasele ngaphambili.

Imeko-bume yoMatshini

Kubalulekile ukuqwalasela imeko yomatshini xa ukhetha izinto ze-CNC. Kuba izixhobo ezahlukeneyo zisabela ngokwahlukileyo kwiimeko ezahlukeneyo zomatshini, njengesantya sokusika, izixhobo zesixhobo, kunye nokupholisa. Imeko-bume yomatshini iquka izinto ezifana nobushushu, ukufuma, kunye nobukho bezingcolisi.

Ngokomzekelo, ezinye izinto zinokuba ne-tension ye-chip okanye i-crack ukuba iqondo lokushisa lomatshini liphezulu kakhulu, ngelixa ezinye zinokufumana ukunxitywa kwesixhobo esigqithisileyo ukuba isantya sokusika siphezulu kakhulu. Ngokufanayo, ukusetyenziswa kwezinto zokupholisa okanye izithambiso ezithile kunokuba yimfuneko ukunciphisa ubushushu kunye nokukhuhlana ngexesha lomatshini. Kodwa ezi zisenokungahambelani nemathiriyeli ethile kwaye zinokukhokelela kumhlwa okanye ezinye iindlela zomonakalo.

Ngoko ke, ukuqwalasela indawo yomatshini kunokuncedisa ukuphucula imveliso, ukunciphisa iindleko, nokuqinisekisa umgangatho wemveliso egqityiweyo.

Inxalenye Ubunzima

Kubalulekile ukuqwalasela inxalenye yobunzima ukuqinisekisa ukusebenza kakuhle kweendleko, ukusebenza, kunye nokwenziwa. Amalungu anzima afuna izinto ezininzi, ezinokunyusa iindleko zokuvelisa. Ukongeza, iindawo ezinzima zinokufuna oomatshini abakhulu nabanamandla ngakumbi be-CNC ukwenza, oko kwandisa iindleko kunye nexesha lokuvelisa. Ngoko ke, ukukhetha izinto ezinobunzima obuphantsi, njenge-aluminium okanye i-magnesium, kunokunceda ukunciphisa ubunzima benxalenye kunye neendleko eziphantsi zokuvelisa.

Ngaphandle koko, ubunzima benxalenye bunokuchaphazela ukusebenza kwemveliso yokugqibela. Ngokomzekelo, kwizicelo ze-aerospace, ukunciphisa ubunzima becandelo kunokunyusa ukusebenza kakuhle kwamafutha kunye nokuphucula ukusebenza ngokubanzi. Kwizicelo zeemoto, ukunciphisa ubunzima kunokuphucula ukusebenza kakuhle kwamafutha, kunye nokunyusa isantya kunye nokuphatha.

Ukumelana nobushushu

Ukumelana nobushushu kuchaphazela ngokuthe ngqo amandla esixhobo sokumelana namaqondo obushushu aphezulu ngaphandle kokufumana uguquko olubalulekileyo okanye umonakalo. Ngexesha lenkqubo yomatshini we-CNC, izinto ezenziwa ngoomatshini zityhubela imijikelo eyahlukeneyo yokufudumeza kunye nokupholisa, ngakumbi xa isikwa, igrunjwa, okanye icolwa. Le mijikelo inokubangela ukwanda kwe-thermal, i-warping, okanye ukuqhekeka kwezixhobo ezingaxhathisi ubushushu.

Ukukhetha izinto ze-CNC ezinokumelana nokushisa okulungileyo kunokunceda ukuphucula inkqubo yomatshini kunye nokunciphisa iindleko zokuvelisa. Xa impahla inokumelana nokushisa okuphezulu, ivumela ukukhawuleza ukusika kunye nokusika okunzulu. Oku kuzisa amaxesha omatshini amafutshane kunye nokuncipha kokunxiba kwezixhobo.

Izixhobo ezahlukeneyo zomatshini we-CNC zinamanqanaba ahlukeneyo okumelana nobushushu, kwaye ukukhethwa kwezinto kuxhomekeke kusetyenziso olucetywayo lwemveliso egqityiweyo. Izinto ezifana ne-aluminium kunye nobhedu zifanelekile kwiindawo zokutshisa ukushisa kunye nezicelo zolawulo lwe-thermal ngenxa ye-conductivity enhle ye-thermal. Kodwa insimbi engenasici kunye ne-titanium ifanelekile kwi-aerospace kunye nezicelo zonyango ngenxa yeendawo eziphezulu zokunyibilika kunye nokuxhathisa ukubola.

Ukuhanjiswa koMbane kunye neeMfuno zeMagnetic

I-conductivity yombane ngumlinganiselo wesakhono sesixhobo sokuqhuba umbane. Kwi-CNC machining, izinto ezinomgangatho ophezulu wombane zikhethwa ngenxa yokuba ziyakwazi ukukhupha ukushisa ngokufanelekileyo. Oku kubaluleke ngakumbi xa kusenziwa iintsimbi, njengoko ubushushu obuveliswa ngexesha lenkqubo bunokubangela ukuba izinto zijike okanye zigqwetheke. Izinto eziphathekayo ezinombane ophezulu, ezifana nobhedu kunye ne-aluminium, zinokutshabalalisa ngokufanelekileyo ukushisa, okunceda ukukhusela le miba.

Iipropati zemagneti zikwabalulekile xa ukhetha izinto ze-CNC, ngakumbi xa usebenza ngezinto ze-ferromagnetic ezifana nentsimbi, i-nickel, kunye ne-cobalt. Ezi zixhobo zinommandla oqinileyo wamagnetic onokuchaphazela inkqubo yokusika. Izinto ezingezizo-magnetic, ezifana ne-titanium kunye nentsimbi engatyiwa, zikhethwa kwi-CNC machining. Ngenxa yokuba abachatshazelwa yintsimi yamagnetic kwaye ngoko bavelise ukusika okucocekileyo.

Ukuqina

Ukucutshungulwa kubhekisa kwindlela ekulula ngayo ukusikwa, ukugrunjwa, okanye ukumiliselwa ngesixhobo somatshini we-CNC.

Xa izinto ze-CNC zinzima kakhulu, kunokuba nzima ukusika okanye ukumila, oku kunokukhokelela ekunxibeni okugqithisileyo kwesixhobo, ukuphuka kwesixhobo, okanye ukugqitywa komgangatho ophantsi. Ngokuchaseneyo, imathiriyeli ethambileyo kakhulu inokugqwesa okanye ijike phantsi kwamandla okusika, ibangele ukuchaneka okungalunganga komgangatho okanye ukugqitywa komphezulu.

Ke ngoko, ukukhetha imathiriyeli yomatshini we-CNC ngobulukhuni obufanelekileyo kubalulekile ekufezekiseni umgangatho ophezulu, izinto ezichanekileyo zoomatshini. Ukongeza, ubunzima bezinto eziphathekayo bunokuchaphazela isantya kunye nokusebenza kakuhle kwenkqubo yomatshini. Ngenxa yokuba izinto ezinzima zinokufuna isantya esicothayo sokusika okanye izixhobo zokusika ezinamandla ngakumbi.

Umphezulu Gqiba

Ukugqitywa komphezulu kuchaphazela ukusebenza kunye nenkangeleko yokugqibela yemveliso eyenziwe ngoomatshini. Umzekelo, indawo enomphezulu orhabaxa inokuba nokukhuhlane ngakumbi, nto leyo enokukhokelela ekunxibeni kwangaphambi kwexesha kunye nokusilela. Kwelinye icala, inxalenye enomphezulu ogudileyo iya kuba nokukhuhlana okuncinci, okukhokelela ekusebenzeni okuphuculweyo kunye nobomi obude. Ukongeza, ukugqitywa komphezulu kudlala indima ebalulekileyo kwi-aesthetics. Ukugqitywa kwendawo epholisiweyo kunokuphucula ukubonakala kwenxalenye kwaye kwenze kube nomtsalane ngakumbi kubathengi.

Ke ngoko, xa ukhetha imathiriyeli yomatshini we-CNC, kubalulekile ukuqwalasela iimfuno zokugqiba umphezulu kwimveliso yokugqibela. Ezinye izinto zilula ukwenza umatshini ukuya kumphezulu ogudileyo ogqityiweyo kunezinye. Umzekelo, iintsimbi ezifana ne-aluminiyam kunye nobhedu kulula ukwenza umatshini ukugqiba kakuhle. Ngokwahlukileyo, izixhobo ezinje nge-carbon fiber kunye ne-fiberglass zinokuba ngumngeni ngakumbi kumatshini, kwaye ukufikelela kumphezulu ogudileyo kunokufuna izixhobo ezikhethekileyo kunye nobuchule.

Ubuhle

Ukuba iprojekthi yakho ye-CNC yomatshini yenzelwe ukuvelisa imveliso eya kusetyenziswa kwindawo ephezulu yokuthengisa, i-aesthetics iya kuba yinto ebalulekileyo. Isixhobo kufuneka sibe nomtsalane ngokubonakalayo, sibe nokwakheka okunomtsalane, umbala, kunye nokugqiba komphezulu. Kufuneka ikwazi ukugudiswa ngokulula, ipeyintiwe, okanye igqitywe ukufezekisa inkangeleko oyifunayo.

Ukongeza, kumashishini afana neemoto kunye ne-aerospace, ubuhle bunokuba luphawu lomgangatho wemveliso kunye nengqalelo yomenzi kwiinkcukacha. Oku kubaluleke kakhulu kwiimoto zodidi, apho abathengi bahlawula i-premium yezinto eziphezulu kunye nokugqiba.

Isicelo

Ukusetyenziswa kokugqibela kwemveliso ngoyena mntu uthatha isigqibo. Ezi zinto zikhankanywe ngasentla zenza inxalenye encinci yazo zonke izizathu umntu aziqwalaselayo ngaphambi kokuba agqibezele izinto ze-CNC. Ezinye izinto eziqhutywa kusetyenziso zinokubandakanya iinkxalabo ezibambekayo ezinje ngobuchule bezinto eziphathekayo, ukuphinda kusebenze iikhemikhali, ukuncamathela, ukufumaneka kwezinto eziphathekayo, ubomi bokudinwa, njl.

Xa kuziwa ekukhetheni izixhobo ezifanelekileyo zeCNC machining, usetyenziso olucetywayo lwemveliso egqityiweyo yinto ebalulekileyo ekufuneka iqwalaselwe. Izixhobo ezahlukeneyo zineempawu ezahlukeneyo, ezinjengokuqina, amandla okuqina, kunye ne-ductility. Ezi zakhiwo zinempembelelo kwindlela izinto ezisebenza ngayo phantsi kweemeko ezithile kwaye zinqume ukufaneleka kwezinto zokusetyenziswa kwezicelo ezahlukeneyo.

Ngokomzekelo, ukuba imveliso egqityiweyo ihloselwe ukusetyenziswa kwindawo ephezulu yokushisa, izinto ezifana ne-aluminium okanye ubhedu ziya kuba lukhetho olungcono ngenxa ye-conductivity ephezulu ye-thermal kunye nokuchasana nomonakalo wokushisa.

Uhlahlo lwabiwo-mali

Uhlahlo lwabiwo-mali yinto ebalulekileyo ekufuneka iqwalaselwe ngenxa yezizathu ezininzi. Okokuqala, iindleko zemathiriyeli zinokuhluka kakhulu ngokuxhomekeke kuhlobo kunye nobungakanani obufunekayo. Ngelixa ezinye iintsimbi zodidi oluphezulu zinokubiza, iiplastiki okanye imidibaniso zinokufikeleleka ngakumbi. Ukuseta uhlahlo lwabiwo-mali lwemathiriyeli kuya kunceda ukunciphisa ukhetho lwakho kwaye ugxininise kwizinto ezingaphakathi kuluhlu lwamaxabiso akho.

Okwesibini, iindleko zokwenza i-CNC zinokubiza kwaye zidle ixesha. Ixabiso lomatshini lixhomekeke kuhlobo lwezinto eziphathekayo, ubunzima benxalenye, kunye nezixhobo ezifunekayo. Ukukhetha imathiriyeli enexabiso eliphantsi kumatshini kunokugcina iindleko zemveliso ziphantsi.

Okokugqibela, ukukhetha izixhobo ezingaphakathi kwebhajethi yakho kunokuchaphazela umgangatho wemveliso egqityiweyo. Iimathiriyeli ezingabizi kakhulu zinokuchaphazeleka ngakumbi okanye zingonakali kunezixhobo ezikumgangatho ophezulu. Ngoko ke, ukubeka uhlahlo lwabiwo-mali kunye nokukhetha izinto ezisemgangathweni ophezulu ngaphakathi kohlahlo lwabiwo-mali kuya kuqinisekisa ukuba imveliso egqityiweyo ihlala ihlala kwaye ikumgangatho ophezulu.

Ezona Mathiriyeli ziBalaseleyo kwiiProjekthi zoMatshini ze-CNC

Ngoku, makhe siqhubele phambili kwinxalenye elandelayo yengxoxo yethu: iintlobo ze-CNC machining materials. Siza kuxubusha ngokweenkcukacha iintsimbi eziqhelekileyo kunye neeplastiki. Kamva, siya kutshintshela ingqalelo yethu kwezinye izixhobo ze-CNC ezingaziwayo.

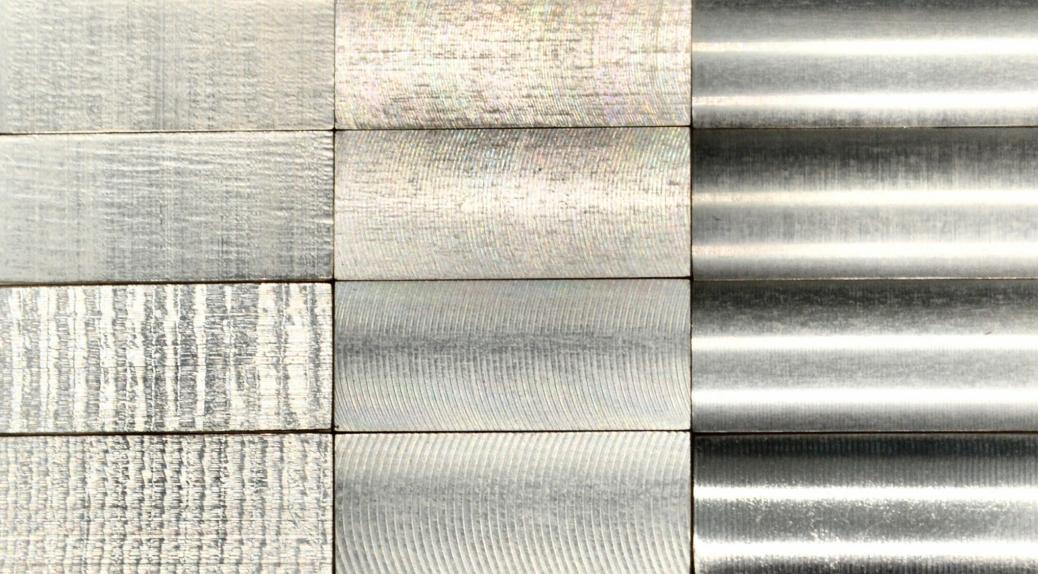

Izixhobo ze-Metal CNC

Izinyithi zezona zinto zixhaphakileyo phakathi kwamalungu omatshini eCNC. Banikezela ngoluhlu olubanzi lweepropathi ezithandekayo ezinje ngokuqina okuphezulu, ubulukhuni, ukumelana nobushushu, kunye nokuhanjiswa kombane.

IAluminiyam (6061, 7075)

I-Aluminiyam ithathwa ngokubanzi njengenye yezona zinto zininzi kwaye zixabisekileyo kwi-CNC machining. Inomlinganiselo okhethekileyo wokomelela ukuya kubunzima, ubume obukhaphukhaphu, ukunganyangeki komhlwa, kunye nenkangeleko emangalisayo yesilivere. Ke, i-aluminiyam inqweneleka kakhulu ukuba isetyenziswe kwiintlobo ngeentlobo zezicelo. Ukongeza, iipropathi zayo ezithandekayo zobushushu kunye nombane ziyenza ilungele ukusetyenziswa kuluhlu lwezicelo zolawulo lwe-elektroniki kunye ne-thermal.

Xa kuthelekiswa nezinye iintsimbi ze-CNC, ezifana ne-titanium kunye nentsimbi, i-aluminiyam ilula kakhulu kumatshini, nto leyo eyenza kube lukhetho oludumileyo kubenzi. Nangona kunjalo, kufuneka kuqatshelwe ukuba i-aluminiyam ayiyona nto iphantsi kakhulu ekhoyo. Kwaye kubiza kakhulu kunezinye izinto ezithile, njengentsimbi engatyiwayo.

Umgangatho ophezulu we-6061 kunye nama-7075 amabakala e-aluminiyam athandwa kakhulu ukuba asetyenziswe kwizakhelo ze-aerospace, iinxalenye ze-injini yemoto, kunye nezixhobo zemidlalo ezikhaphukhaphu. Nangona kunjalo, ukuguquguquka kwe-aluminiyam kuthetha ukuba isetyenziswa kwamanye amashishini amaninzi kunye nezicelo, kubandakanya ukwakhiwa, ukupakishwa, kunye nombane wabathengi.

Intsimbi engatyiwa (316, 303, 304)

Intsimbi engenastainless iza ngamabakala amaninzi. Ngokubanzi, nangona kunjalo, inamandla aphezulu kunye nokuqina, ukuxhathisa ukunxiba, kunye nokuxhathisa ukubola, kwaye inkangeleko emenyezelayo njenge-aluminiyam. Ngaphaya koko, iphakathi kweentsimbi zamaxabiso aphakathi. Nangona kunjalo, yinto enzima kumatshini we-CNC ngenxa yobunzima bayo.

I-316 SS iluncedo kwizicelo zaselwandle, izixhobo zonyango, kunye neendawo ezivaliweyo zangaphandle ngenxa yokukwazi ukumelana nobushushu kunye nomhlwa. I-303 kunye ne-314 zabelana ngokuqamba okufanayo kwaye zixabisa kakhulu kwaye zisebenza ngakumbi kune-316. Usetyenziso lwazo oluphambili lubandakanya iziqhoboshi (iibholithi, izikrufu, iibhushi, njl.njl.), iinxalenye zemoto, kunye nezixhobo zasekhaya.

Intsimbi yeCarbon kunye ne-alloy Steel

Intsimbi yekhabhoni kunye neealloyi ezinxulumeneyo zinika amandla abalaseleyo kunye nokusebenza kakuhle, zizenza zilungele ukusetyenziswa kwizicelo ezininzi. Zikwahambelana neenkqubo ezahlukeneyo zokunyanga ukushisa, ukuphucula ngakumbi iimpawu zabo zomatshini. Ngaphezu koko, intsimbi ye-carbon ayibizi kakhulu xa ithelekiswa nezinye isinyithi ze-CNC.

Nangona kunjalo, kuyafaneleka ukuba uqaphele ukuba i-carbon steel kunye ne-alloys zayo azikwazi ukumelana ne-corrosion, ngokungafaniyo nezixhobo ezifana nensimbi engenasici okanye i-aluminium. Ukongeza, inkangeleko yabo erhabaxa isenokungafaneleki kwizicelo zobuhle.

Nangona kunjalo, intsimbi yekhabhoni kunye nealloys zayo zinemisebenzi emininzi esebenzayo, kubandakanywa iziqhoboshi zoomatshini kunye nezakhiwo ezinje ngemiqadi. Ngaphandle kwemida yazo, ezi zixhobo zihlala zithandwa kukhetho lwemizi-mveliso emininzi kunye nemveliso ngenxa yamandla azo, ukufikeleleka, kunye nobuchule.

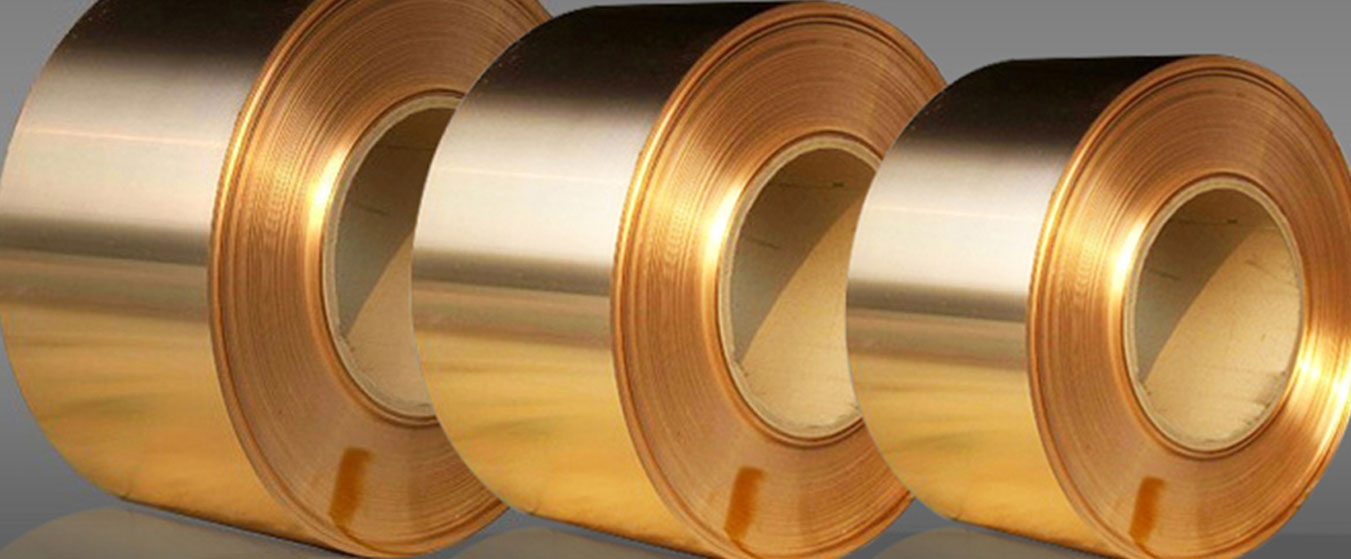

Ubhedu

I-Brass yintsimbi eguquguqukayo eyaziwa ngokusebenza kwayo okugqwesileyo, ukuxhathisa ukubola, kunye nokuhanjiswa kwe-thermal kunye nombane. Ikwaqhayisa ngenkangeleko enomtsalane ngenxa yobhedu lwayo, kunye neempawu ezibalaseleyo zokukhuhlana komphezulu.

I-Brass ifumana izicelo ezininzi kumashishini ahlukeneyo. Umzekelo, iqhele ukusetyenziswa kwiimveliso zabathengi, iziqhoboshi ezisezantsi, imibhobho yamanzi kunye nezixhobo zombane. Iipropathi zayo ziyenza ibe lolona khetho lufanelekileyo kumacandelo okuvelisa afuna ukuqina kunye namandla ngelixa igcina isibheno sobuhle.

Ubhedu

ICopper idume ngokugqwesa kombane kunye ne-thermal conductivity. Nangona kunjalo, kunokuba ngumceli mngeni kumatshini ngenxa yokonakala okuphezulu. Oku kunokubangela ubunzima ekuveliseni iitshiphusi ngexesha lomatshini we-CNC. Ukongezelela, ubhedu luxhomekeke kwi-corrosion, enokuthi ibe yinkxalabo kwiindawo ezithile.

Phezu kwayo nje le mingeni, ubhedu lusetyenziswa kakhulu kwimizi-mveliso eyahlukahlukeneyo, kuquka iingcingo zombane, iimveliso zemagnethi, nokwenza izacholo. Iimpawu zayo ze-conductivity ezigqwesileyo zenza ukuba kube yinto efanelekileyo yokukhetha umbane kunye ne-electronic applications, ngelixa i-malleability yayo kunye nesibheno sobuhle senza ukuba kube lukhetho oludumileyo kwishishini lobucwebe.

I-Titanium

Iialloyi ze-Titanium zaziwa ngokwamandla azo akhethekileyo kubunzima bomlinganiselo, nto leyo ezenza zibe khaphukhaphu kwaye zomelele ngaxeshanye. Kananjalo ziyakwazi ukumelana ne-corrosion kwaye zine-conductivity elungileyo yobushushu. Ukongezelela, i-titanium i-biocompatible, ngoko ke ifanelekile kwizicelo ze-biomedical.

Nangona kunjalo, kukho ezinye iingxaki ekusebenziseni i-titanium. Umbane awuhambi kakuhle kwaye kunzima ukuwumatshini. I-HSS eqhelekileyo okanye i-carbide cutters ebuthathaka ayifanelekanga ukuyenza, kwaye yinto ebiza kakhulu ukuyisebenzisa kwimveliso ye-CNC.

Nangona kunjalo, i-titanium sisixhobo esithandwayo somatshini we-CNC, ngakumbi kwiindawo eziphezulu ze-aerospace, izixhobo zomkhosi, kunye neemveliso zebhayoloji ezifana nokufakelwa.

Magnesium

I-Magnesium yintsimbi edibanisa amandla kunye nobunzima obuphantsi. Iimpawu zayo ezibalaseleyo zobushushu ziyenza ilungele ukusetyenziswa kwindawo ezinobushushu obuphezulu, njengeenjini. Ubume bayo obukhaphukhaphu buvumela ukuveliswa kwezithuthi ezikhaphukhaphu kunye nezonga amafutha.

Nangona kunjalo, i-magnesium iyaziwa ngokuvutha kwayo, enokuyenza ibe yinkxalabo yokhuseleko kwizicelo ezithile. Ukongeza, ayixhathisi ukudumba njengezinye iintsimbi, ezinje nge-aluminium, kwaye inokubiza kakhulu kumatshini.

Izinto zePlastiki zeCNC

Ngoku siza kuxoxa ngeeplastiki ze-CNC. Nangona uninzi lwezixhobo zeplastiki zingenako ukusebenziseka ngenxa yokuqina kwazo okuphantsi kunye namanqaku okunyibilika, sikhethe iqela elincinci elinezicelo ze-CNC ezibanzi.

IAcetal (POM)

I-Acetal yiplastiki ye-CNC enemisebenzi emininzi enoluhlu lwezinto ezinqwenelekayo. Iqhayisa ngokudinwa okugqwesileyo kunye nokuxhathisa impembelelo, ukuqina okundilisekileyo, kunye ne-coefficients ephantsi ye-friction. Ngaphandle koko, iyamelana kakhulu nokufuma, nto leyo eyenza ukuba ibe lolona khetho lubalaseleyo lokusetyenziswa kwiindawo ezifumileyo.

Enye yeenzuzo eziphambili ze-acetal kukuqina kwayo, okwenza kube lula umatshini ngokuchaneka okukhulu. Oku kwenza kube lukhetho oludumileyo lokusetyenziswa kumacandelo achanekileyo anje ngeebheringi, iigiya, kunye neevalvu. Ngenxa yeepropathi zayo ezigqwesileyo zoomatshini kunye nokuchasana okuphezulu kwezinto zokusingqongileyo, i-Acetal lukhetho olunokuthenjwa kumashishini ahlukeneyo, njengeemoto, i-aerospace, kunye nempahla yabathengi.

I-Akriliki (PMMA)

I-Acrylic yinto esetyenziswa ngokuqhelekileyo enokuthi ithathe indawo yeglasi ngenxa yezinto ezinqwenelekayo. Inobungqongqo obuhle kunye nokucaca kwe-optical, evumela ukuba isetyenziswe kwizicelo apho i-face-through surface iyimfuneko. Amacandelo e-Acrylic anika enye indlela ekhangayo kunye nesebenzayo kwiglasi, kunye nokucaca kakuhle kwe-optical kunye neqondo eliphezulu lokuqina.

Ngelixa i-acrylic inezithintelo ezithile, ezinje ngokuba sesichengeni sokuqhekeka kunye nokuthamba kwe-thermal, ihlala iyimathiriyeli eyaziwayo ye-CNC machining ngenxa yokuguquguquka kwayo kunye nokusebenziseka ngokulula. Ngokukwazi ukwenza izinto ezichanekileyo, ezikumgangatho ophezulu, i-acrylic lukhetho olubalaseleyo kuluhlu olubanzi lwezicelo. Iilensi, iindawo ezivaliweyo, izitya zokugcina ukutya, kunye nezinto zokuhombisa ziyimizekelo nje embalwa.

Polycarbonate (PC)

I-Polycarbonate (i-PC) yimathiriyeli yeplastiki eyaziwayo esetyenziselwa umatshini we-CNC ngenxa yeepropati zayo ezizodwa. Icace kakhulu, iyenza ibe sisixhobo esifanelekileyo sokusetyenziswa kwiimveliso ezifuna ukucaca, njengeeglasi zokhuseleko, izixhobo zonyango, kunye neziboniso zombane. Ngaphaya koko, inokumelana nobushushu obulungileyo ngoko ikulungele ukusetyenziswa kwizicelo zobushushu obuphezulu.

Nangona kunjalo, ukuchaphazeleka kwayo ekukrweleni kunye nokungabikho kokuchasana kwe-UV kunokunciphisa ukusetyenziswa kwayo kwizicelo ezithile. Ukuba sesichengeni selanga ixesha elide kunokubangela ukuba libe tyheli kwaye libe rhabaxa. Oku kunokunqanda ukusetyenziswa kwayo kwizicelo zangaphandle ngaphandle kokuba iguqulwe nge-UV stabilizers.

Olunye usetyenziso oluqhelekileyo lwePC kukuveliswa kweeglasi zokhuseleko kunye nezikhuselo zobuso, apho ukuchasana kwayo neempembelelo kunye nokungafihli nto kwenza kube lukhetho olufanelekileyo. I-PC ikwasetyenziswa ekuveliseni iinxalenye zeemoto, izinto zombane, kunye nezixhobo zonyango.

Iipolypropylene (PP)

Ipolypropylene yipolymer eguquguqukayo enezibonelelo ezininzi, kubandakanya ukumelana neekhemikhali eziphezulu kunye namandla okudinwa. Ikwayinto ekumgangatho wezonyango, kwaye ivelisa umphezulu ogudileyo ukugqiba xa machining CNC. Nangona kunjalo, enye yezithintelo zayo kukuba ayinakumelana namaqondo aphezulu aphezulu, njengoko ithambekele ekuthobeni kunye nenyongo ngexesha lokusika, okwenza kube nzima kumatshini.

I-Polypropylene ihlala ithandwa kakhulu kwizicelo ezahlukeneyo. Iimpawu zayo ezibalaseleyo zenza ukuba zilungele ukwenza iigiya kunye neemveliso zonyango.

ABS

I-ABS sisixhobo seplastiki esinexabiso eliphezulu nesifaneleke kakuhle kwi-CNC machining ngenxa yobuchule bayo obugqwesileyo, ukomelela, ukuxhathisa impembelelo, kunye nokumelana neekhemikhali. Ngaphezu koko, inokuba nemibala ngokulula, iyenze ilungele izicelo apho i-aesthetics ibalulekile.

Nangona kunjalo, i-ABS ayifanelekanga ukusetyenziswa kwiindawo ezinobushushu obuphezulu kwaye ayinayo i-biodegradable. Ngaphandle koko, ivelisa umsi ongathandekiyo xa utshiswa, onokuthi ube yinkxalabo kwivenkile ye-CNC.

I-ABS inezicelo ezininzi kwaye iqhele ukusetyenziswa kushicilelo lwe-3D kunye nokubumba isitofu, rhoqo ngokwenziwa kwe-post-processing kusetyenziswa umatshini we-CNC. Ihlala isetyenziselwa ukwenza amacandelo eemoto, kunye neendawo ezivaliweyo zokukhusela, kunye neprototyping ekhawulezayo.

Inayiloni

Inayiloni yimathiriyeli eguquguqukayo enamandla amakhulu okuqina, ukuqina, kunye nokumelana nempembelelo. Ingasetyenziswa kwiintlobo ngeentlobo zeembumba, ezifana nenayiloni eyomeleziweyo yeglasi-ifayibha, kwaye inamandla omgangatho ophezulu wokuthambisa. Nangona kunjalo, ayikhuthazwa ukuba isetyenziswe kwiindawo ezifumileyo.

Inayiloni ifaneleke ngokukodwa kwizicelo ezifuna ukukhuselwa kwimikhosi ekhukhulayo. Oku kubandakanya amacandelo anje ngegiya, umphezulu wokutyibilika, iibheringi, kunye nesprockets. Ngamandla ayo aphezulu kunye neempawu zokuthambisa, inayiloni lukhetho oludumileyo kwiimveliso ezininzi zeshishini kunye nezemidlalo.

UHMW-PE

I-UHMWPE yimathiriyeli ethandwayo ngenxa yeempawu zayo ezikhethekileyo, kubandakanywa ukuqina okuphezulu, ukukrazuka kunye nokunganyangeki kunye nokuqina. Nangona kunjalo, ukungazinzi kwayo kwe-thermal ngexesha lomatshini kwenza kube nzima kumatshini.

Ngaphandle kobunzima bokwenza oomatshini, i-UHMWPE sisixhobo esigqwesileyo se-CNC sokwenza izinto ezityibilikayo kwiibheringi, iigiya, kunye neerola. Iimpawu zayo ezibalaseleyo zenza ukuba zilungele izicelo apho ukuxhatshazwa okuphezulu kunye nokuqina kuyadingeka. Xa isenziwa ngoomatshini ngokuchanekileyo, i-UHMWPE inokubonelela ngokusebenza okugqwesileyo kunye nobomi obude xa kuthelekiswa nezinye izinto.

Ezinye Izinto

CNC machining ngokuqhelekileyo isebenzisa iintsimbi kunye neeplastiki, kodwa inokuphinda isebenze nezinye izinto ezininzi, kuquka ezi zidweliswe ngezantsi.

Ugwebu

Amagwebu luhlobo lwezinto ze-CNC ezibonakaliswa ngumzimba oqinileyo kunye ne-voids ezaliswe ngumoya. Esi sakhiwo esiyingqayizivele sinika amagwebu ubume obubonakalayo kunye nokukhanya okuphawulekayo. Amagwebu athile anoxinano oluphezulu, anje nge-polyurethane foam kunye ne-Styrofoam, anokwenziwa lula ngoomatshini ngenxa yokuqina, amandla, ukukhaphukhaphu, kunye nokuqina.

Ubume be-Foams bukhaphukhaphu bubenza babe lolona khetho lubalaseleyo lokupakishwa kokhuselo. Ukuguquguquka kwazo ekwenziweni komatshini kwiimilo ezahlukeneyo kunye nobukhulu kubenza babe luncedo ngokulinganayo ekudaleni izinto zokuhombisa. Ngaphandle koko, iipropathi zabo zokugquma zibenza ukuba babe lukhetho oludumileyo lwe-thermal insulation kwizakhiwo, iiyunithi zefriji, kunye nezinye izicelo apho ukulawula ubushushu kubalulekile.

Iinkuni

Ukhuni sisixhobo esisetyenziswa ngokubanzi kwi-CNC machining ngenxa yokukhululeka komatshini, amandla amahle kunye nobunzima, kunye noluhlu olubanzi lweentlobo ezikhoyo. Ukongezelela, ukhuni luyi-organic compound kwaye alunampembelelo embi kwindalo. Ngenxa yokuguquguquka kwayo kunye nokubukeka kobuhle, umthi lukhetho oludumileyo lwefenitshala, ukuhombisa ikhaya, kunye neeprojekthi ze-DIY.

Nangona kunjalo, ukwenziwa kweenkuni kuvelisa uthuli oluninzi, olunokuthi lube sengozini yempilo kubasebenzi. Ngoko ke, kubalulekile kwiindibano zocweyo zokwenziwa kweenkuni zibeneenkqubo zolawulo olululo.

Iimbumba

Ii-Composites zizixhobo ezenziwe ngamacandelo amabini okanye ngaphezulu adityaniswe kunye ne-bonding medium. Izinto eziqhelekileyo ezidibeneyo ezisetyenziswa kwi-CNC machining ziquka i-carbon fiber, i-plywood, i-fiberglass, kunye nezinye. Ezi zixhobo zinezicelo kumashishini ahlukeneyo, njengeemoto, inqwelomoya, ezemidlalo, kunye nezonyango.

Iicomposites zoMatshini zinokuba ngumngeni kakhulu ngenxa yezinto ezininzi. Izinto eziqulethweyo kwii-composites zinokuba neempawu ezahlukeneyo zoomatshini kunye neefom, ezinje ngeefiber, iishadi, okanye iipleyiti. Ngaphezu koko, i-bonding medium ngokwayo ingaba neepropati ezizodwa ezimele zithathelwe ingqalelo ngexesha lenkqubo yomatshini.

Ungalibali ukuqwalasela izinto ezinokubakho ze-CNC

Iindidi ezityebileyo kwizinto zomatshini ze-CNC ngamanye amaxesha zinokubangela ukudideka ngakumbi kunenzuzo. Yinto eqhelekileyo ukungahoywa kwezixhobo ze-CNC ezingaphaya kweentsimbi eziqhelekileyo kunye neeplastiki.

Ukukunceda ujonge umfanekiso omkhulu ngelixa uYila ukuVelisa, ngezantsi kuluhlu olufutshane lwamanqaku ekufuneka uwaqwalasele phambi kokuba ugqibezele imathiriyeli yeprojekthi yakho!

Khetha iMathiriyeli engeyiyo iMetal: Kukho iimeko ezininzi apho imathiriyeli engeyiyo isinyithi ilingana endaweni yesinyithi. Iiplastiki eziqinileyo ezifana ne-ABS okanye i-UHMW-PE ziqinile, ziqinile, kwaye zihlala zihlala njalo, umzekelo. Ii-composites ezifana ne-carbon fiber nazo zithathwa njengezona ziphezulu kwiintsimbi ezininzi ezenza kakuhle.

Cinga ngePhenolics: I-Phenolics luhlobo lwezinto ezidibeneyo ezingabizi kakhulu kunye nokuqina okuphezulu kunye neempawu eziphezulu. Zilula ukuzisebenzisa kumatshini kwaye zinokusikwa ngesantya esiphezulu kakhulu, ukonga ixesha kunye nemali.

Yazi iiPlastiki ezahlukeneyo: Ukuba nolwazi malunga nepotifoliyo epheleleyo yeplastiki ye-CNC yomatshini wokwenza izinto kufuneka ube nobuchule kubaqulunqi. Iiplastiki ze-CNC zixabiso eliphantsi, kulula ukuzisebenzisa, kwaye ziza kuluhlu olwahlukeneyo lweempawu eziphathekayo ezingenakuhoywa.

Khetha iLungelo phakathi kwamaFoams ahlukeneyo: Ngokubhekiselele kwicandelo elingentla malunga namagwebu, singathanda ukugxininisa ukuba inamandla amaninzi njengezinto ze-CNC. Kwanamanye amacandelo omatshini we-CNC ngoku enziwe ngamagwebu esinyithi! Funda iifoam ezahlukeneyo ze-CNC ukuze ubone ukuba yeyiphi ekulungela usetyenziso lwakho.

IiProjekthi zoMatshini ezahlukeneyo ze-CNC kunye neZibonelelo, uMthombo omnye

Uyilo lwemveliso ngumba obalulekileyo kushishino lwangoku. Njengoko isayensi yezinto iqhubela phambili, umatshini weCNC uye wathembela ngakumbi ekukhetheni izinto ezicingayo. E-Guan Sheng, sisebenza ngokukhethekileyo kwiinkonzo zokwenza oomatshini be-CNC, kuquka ukucola nokujika kwe-CNC, kwaye sinikezela ngoluhlu olubanzi lwezixhobo, ukusuka kwiintsimbi ezifunwayo ukuya kwiiplastiki ezikumgangatho ophezulu. I-5-axis yethu yezakhono zomatshini, ezidityaniswe neqela lethu elinamava, zisivumela ukuba sinikeze ukuchaneka okungenakulinganiswa kunye nomgangatho kubathengi bethu.

Sizinikezele ekuboneleleni ngenkonzo yabathengi ekhethekileyo kwaye sizimisele ukunceda abathengi bethu banciphise iindleko kwaye bafezekise iinjongo zabo. Iqela lethu lobuchwephesha liyafumaneka ukukunceda ekukhetheni ezona mathiriyeli zibalaseleyo zeprojekthi yakho kwaye linokubonelela ngeengcebiso zeengcali ngaphandle kwentlawulo. Nokuba ufuna iinxalenye zomatshini we-CNC okanye uneprojekthi ethile engqondweni, silapha ukukunceda inyathelo ngalinye lendlela.

Ixesha lokuposa: Jul-07-2023