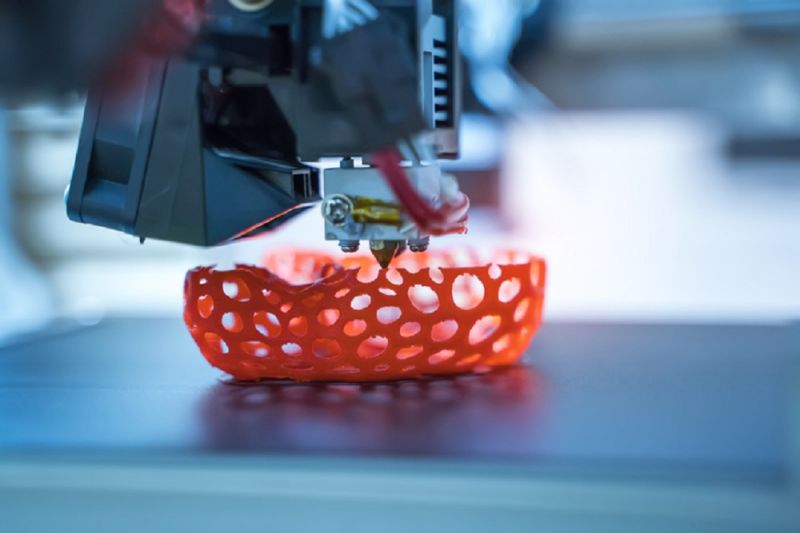

Ngelixa uninzi lomsebenzi wokwenziwa wenziwa ngaphakathi komshicileli we-3D njengoko iinxalenye zakhiwe umaleko ngokwemaleko, ayisosiphelo senkqubo eso. I-Post-processing linyathelo elibalulekileyo kwi-3D yoshicilelo lokuhamba komsebenzi ojika amacandelo ashicilelweyo kwiimveliso ezigqityiweyo. Oko kukuthi, "i-post-processing" ngokwayo ayisiyonkqubo ethile, kodwa kunoko udidi olubandakanya iindlela ezininzi zokucwangcisa kunye nobuchule obunokusetyenziswa kwaye zidibaniswe ukuhlangabezana neemfuno ezahlukeneyo zobuhle kunye nokusebenza.

Njengoko siza kubona ngokweenkcukacha kweli nqaku, kukho iindlela ezininzi emva kokulungiswa kunye nokugqiba umphezulu, kubandakanywa nesiseko se-post-processing (njengokususwa kwenkxaso), i-surface smoothing (ngokomzimba kunye neekhemikhali), kunye nokulungiswa kombala. Ukuqonda iinkqubo ezahlukeneyo onokuzisebenzisa kushicilelo lwe-3D kuya kukuvumela ukuba ufezekise ukucaciswa kwemveliso kunye neemfuno, nokuba injongo yakho kukufezekisa umgangatho ofanayo womphezulu, ubuhle obuthile, okanye ukwanda kwemveliso. Makhe sihlolisise.

Isiseko se-post-processing ngokuqhelekileyo sibhekisela kumanyathelo okuqala emva kokususa kunye nokucoca inxalenye eprintiweyo ye-3D kwiqokobhe lendibano, kubandakanywa ukususwa kwenkxaso kunye nokugudisa okusisiseko komphezulu (ukulungiselela iindlela zokugudisa ngokucokisekileyo).

Iinkqubo ezininzi zokushicilela ze-3D, ezibandakanya i-fused deposition modeling (FDM), i-stereolithography (SLA), i-laser sintering yensimbi ethe ngqo (DMLS), kunye ne-carbon digital light synthesis (DLS), ifuna ukusetyenziswa kwezakhiwo zenkxaso ukudala i-protrusions, iibhuloho, kunye nezakhiwo ezibuthathaka. . okukhethekileyo. Nangona ezi zakhiwo ziluncedo kwinkqubo yoshicilelo, kufuneka zisuswe ngaphambi kokuba iindlela zokugqiba zisetyenziswe.

Ukususa inkxaso kunokwenziwa ngeendlela ezininzi ezahlukeneyo, kodwa inkqubo eqhelekileyo namhlanje ibandakanya umsebenzi wezandla, njengokusika, ukususa inkxaso. Xa usebenzisa i-substrates e-soluble yamanzi, isakhiwo senkxaso sinokususwa ngokuntywiliselwa into eprintiweyo emanzini. Kukwakho nezisombululo ezikhethekileyo zokususwa kwenxalenye ngokuzenzekelayo, ngakumbi ukwenziwa kokongeza isinyithi, esebenzisa izixhobo ezinje ngoomatshini be-CNC kunye neerobhothi ukusika ngokuchanekileyo inkxaso kunye nokugcina ukunyamezelana.

Enye indlela esisiseko yasemva kokulungiswa kukuqhunyiswa kwesanti. Inkqubo ibandakanya ukutshiza iinxalenye eziprintiweyo ngamaqhekeza phantsi koxinzelelo oluphezulu. Impembelelo yezinto zokutshiza kwindawo yokuprinta idala i-smooth, i-texture efanayo.

I-Sandblasting idla ngokuba linyathelo lokuqala lokugudisa umphezulu oshicilelweyo we-3D njengoko isusa ngokufanelekileyo imathiriyeli eshiyekileyo kwaye idala umphezulu ofanayo ngakumbi othi emva koko ulungele amanyathelo alandelayo afana nokupholisha, ukupeyinta okanye ukudyobha. Kubalulekile ukuqaphela ukuba i-sandblasting ayivelisi ukugqiba okukhazimlayo okanye okukhazimlayo.

Ngaphandle kwesiseko se-sandblasting, kukho ezinye iindlela zokwenziwa emva kokulungiswa ezinokuthi zisetyenziswe ukuphucula ukugudiswa kunye nezinye iipropathi ezingaphezulu zamacandelo ashicilelweyo, njengembonakalo ye-matte okanye ecwebezelayo. Kwezinye iimeko, iindlela zokugqiba zingasetyenziselwa ukufezekisa ukuguquguquka xa usebenzisa izinto zokwakha ezahlukeneyo kunye neenkqubo zokushicilela. Nangona kunjalo, kwezinye iimeko, ukugudiswa komphezulu kulungele kuphela iintlobo ezithile zemidiya okanye ushicilelo. Icandelo lejometri kunye nemathiriyeli yoshicilelo zezona zinto zimbini zibalulekileyo xa ukhetha enye yezi ndlela zilandelayo zokugudisa umphezulu (zonke zifumaneka kwiXometry Amaxabiso akhawulezayo).

Le ndlela yokuthunyelwa kwe-post-processing ifana ne-sandblasting yemidiya eqhelekileyo kuba ibandakanya ukusebenzisa amaqhekeza ekushicileleni phantsi koxinzelelo oluphezulu. Nangona kunjalo, kukho umahluko obalulekileyo: i-sandblasting ayisebenzisi nawaphi na amasuntswana (afana nesanti), kodwa isebenzisa amaso eglasi angqukuva njengento ephakathi ukuya kwi-sandblast eprintiweyo ngesantya esiphezulu.

Impembelelo yeentsimbi zeglasi ejikelezileyo kumphezulu wokushicilela kudala umphumo ocacileyo kunye nofanayo. Ukongeza kwiinzuzo zobuhle be-sandblasting, inkqubo yokucoca ikwandisa amandla omatshini wenxalenye ngaphandle kokuchaphazela ubungakanani bayo. Oku kungenxa yokuba imilo engqukuva yamaso eglasi inokuba nefuthe elingaphezulu kakhulu kumphezulu wenxalenye.

I-Tumbling, ekwabizwa ngokuba yi-screening, sisisombululo esisebenzayo kwi-post-processing iinxalenye ezincinci. Itekhnoloji ibandakanya ukubeka i-3D yokuprinta kwidrama kunye neencinci ezincinci ze-ceramic, iplastiki okanye isinyithi. Emva koko igubu lijikeleza okanye lingcangcazela, libangela ukuba i-debris igubungele kwindawo eprintiweyo, isuse naziphi na izitenxo zomhlaba kunye nokudala indawo egudileyo.

Ukuwa kweMedia kunamandla ngakumbi kunokudubula kwesanti, kwaye ukuguda komphezulu kunokulungiswa ngokuxhomekeke kuhlobo lwezinto eziwayo. Ngokomzekelo, ungasebenzisa i-media-grain-grain media ukuze wenze i-rougher surface texture, ngelixa usebenzisa i-chips ephezulu yegrit inokuvelisa indawo epholileyo. Ezinye zezona nkqubo ziqhelekileyo zokugqiba ezinkulu zinokubamba iinxalenye ezinomlinganiselo we-400 x 120 x 120 mm okanye 200 x 200 x 200 mm. Kwezinye iimeko, ngakumbi ngeengxenye ze-MJF okanye ze-SLS, indibano inokudityaniswa ipholishelwe ngumthwali.

Ngelixa zonke ezi ndlela zingasentla zokugudisa zisekwe kwiinkqubo zomzimba, ukugudisa umphunga kuxhomekeke kwisenzo sekhemikhali phakathi kwezinto eziprintiweyo kunye nomphunga ukuvelisa umphezulu ogudileyo. Ngokukodwa, ukugudisa umphunga kubandakanya ukuveza ushicilelo lwe-3D kwisinyibilikisi esiphuphumayo (njenge-FA 326) kwigumbi lokulungisa elitywiniweyo. I-steam ibambelela kumphezulu wokushicilela kwaye idala ukunyibilika kweekhemikhali ezilawulwayo, ukugudisa nakuphi na ukungafezeki kwendawo, iinduli kunye neentlambo ngokusabalalisa kwakhona izinto ezityhidiweyo.

Ukugudisa umphunga kukwakwaziwa ukunika umphezulu umphezulu ogudisiweyo kwaye ubengezelayo. Ngokuqhelekileyo, inkqubo yokugudisa umphunga ibiza kakhulu kunokugudiswa komzimba, kodwa ikhethwa ngenxa yokuguda kwayo okugqwesileyo kunye nokugqiba okumenyezelayo. I-Vapor Smoothing iyahambelana neepolima ezininzi kunye nemathiriyeli yoshicilelo ye-3D elastomeric.

Ukufaka imibala njengenyathelo elongezelelweyo emva kokulungiswa yindlela entle yokuphucula i-aesthetics yemveliso yakho eprintiweyo. Nangona izixhobo zokuprinta ze-3D (ngokukodwa iifayili ze-FDM) ziza kwiindlela ezahlukeneyo zombala, i-toning njengenkqubo ye-post-process ikuvumela ukuba usebenzise izixhobo kunye neenkqubo zokuprinta ezihlangabezana neenkcukacha zemveliso kwaye ufezekise umbala ochanekileyo wezinto eziphathekayo. imveliso. Nazi iindlela ezimbini ezixhaphakileyo zokufaka imibala kushicilelo lwe-3D.

Ukupeyinta ukutshiza yindlela eyaziwayo ebandakanya ukusebenzisa isitshizi se-aerosol ukufaka umaleko wepeyinti kushicilelo lwe-3D. Ngokumisa ushicilelo lwe-3D, unokutshiza ipeyinti ngokulinganayo phezu kwendawo, ukugquma yonke indawo yayo. (Ipeyinti ingasetyenziswa ngokukhethayo kusetyenziswa ubuchule bokugquma.) Le ndlela ixhaphakile kuzo zombini iindawo eziprintiweyo ze-3D nezingoomatshini kwaye ayibizi kakhulu. Nangona kunjalo, ine-drawback enye enkulu: ekubeni i-inki isetyenziswe kakhulu, ukuba inxalenye eprintiweyo ikhutshwe okanye igugile, umbala wokuqala wezinto eziprintiweyo ziya kubonakala. Le nkqubo ilandelayo ye-shading isombulula le ngxaki.

Ngokungafaniyo nepeyinti yokutshiza okanye ibrashi, i-inki ekushicileleni kwe-3D ingena ngaphantsi komhlaba. Oku kuneengenelo ezininzi. Okokuqala, ukuba ushicilelo lwe-3D luyaguga okanye lukrweleke, imibala yalo edlamkileyo iya kuhlala injalo. Ibala nalo alisuki, nto leyo eyaziwa ngokuba yipeyinti. Enye inzuzo enkulu yokudaya kukuba ayichaphazeli ukuchaneka kwe-dimensional yokushicilela: ekubeni idayi ingena kumphezulu wemodeli, ayifaki ubuninzi kwaye ngoko ayiphumeleli ekulahlekelweni kweenkcukacha. Inkqubo ethile yombala ixhomekeke kwinkqubo yoshicilelo lwe-3D kunye nezixhobo.

Zonke ezi nkqubo zokugqiba zinokwenzeka xa usebenza nomlingane wokuvelisa njengeXometry, ekuvumela ukuba wenze iiprinta ze-3D zobuchwephesha ezihlangabezana nemigangatho yokusebenza kunye nobuhle.

Ixesha lokuposa: Apr-24-2024