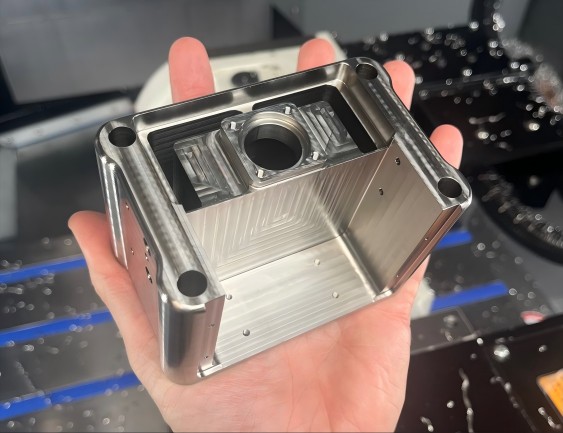

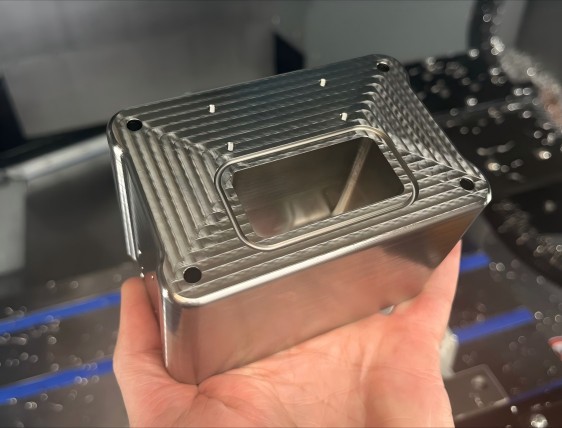

Ngoku kutshanje senze i-batch ye-stainless steel parts.Imfuno yokuchaneka iphezulu kakhulu, efuna ukufikelela kwi-± 0.2μm. Izinto zentsimbi engatyiwayo zinzima ngokwentelekiso. KwiCNC machining izinto zentsimbi stainless, amanyathelo ahambelanayo anokuthathwa kwi-pre-processing preparation, control process process and post-processing ukuphucula ukuchaneka kokulungiswa. Le ilandelayo yindlela ekhethekileyo:

Ukulungiswa kwangaphambili kokulungiswa

• Khetha isixhobo esifanelekileyo: ngokweempawu zezinto zensimbi ezingenasici, ezifana nobunzima obuphezulu, ukuqina, njl., Khetha isixhobo esinobunzima obuphezulu, ukuxhatshazwa okuphezulu kunye nokumelana nokubambelela kakuhle, njengezixhobo ze-tungsten cobalt carbide okanye izixhobo eziboshwe.

• Yandisa isicwangciso senkqubo: qulunqa iindlela zenkqubo yokusetyenzwa eneenkcukacha nezifanelekileyo, cwangcisa ngokufanelekileyo ukurhabaxa, ukugqibezela ngokulinganayo kunye nokugqiba, kwaye ushiye umda wokulungisa oyi-0.5-1mm ukulungiselela ukusetyenzwa okuphezulu okuchanekileyo.

• Lungiselela iindawo ezingenanto ezikumgangatho ophezulu: Qinisekisa umgangatho ofanayo wemathiriyeli engenanto kwaye akukho ziphene zangaphakathi ukunciphisa iimpazamo zokuchaneka komatshini ezibangelwa yimathiriyeli ngokwayo.

Ulawulo lwenkqubo

• Lungiselela iiparamitha zokusika: Misela iiparamitha ezifanelekileyo zokusika ngovavanyo kunye namava okuqokelela. Ngokubanzi, ukusetyenziswa kwesantya esisezantsi sokusika, ukondla okuphakathi kunye nobunzulu bokusika obuncinci kunokunciphisa ngempumelelo ukunxiba kwesixhobo kunye nokuguqulwa komatshini.

• Ukusetyenziswa kwe-lubrication yokupholisa efanelekileyo: ukusetyenziswa kwamanzi okusika kunye nokupholisa okulungileyo kunye neempawu zokuthambisa, ezifana ne-emulsion equkethe izongezo zoxinzelelo olugqithisileyo okanye i-synthetic cutting fluids, inokunciphisa ubushushu bokusika, ukunciphisa ukungqubuzana phakathi kwesixhobo kunye ne-workpiece, inqanda ukuveliswa kwezicubu ze-chip, ngaloo ndlela kuphuculwe ukuchaneka kokucubungula.

• Ukulungiswa kwendlela yesixhobo: Ngexesha lenkqubo, indlela yesixhobo iphuculwe, kwaye imowudi yokusika efanelekileyo kunye ne-trajectory yamkelwa ukuphepha ukujika okubukhali kwesixhobo kunye nokukhawuleza rhoqo kunye nokunciphisa, ukunciphisa ukuguquguquka kwamandla okusika, kunye nokuphucula umgangatho kunye nokuchaneka kwendawo yokucoca.

• Ukuphunyezwa kokufunyanwa kwe-intanethi kunye nembuyekezo: ixhotyiswe ngenkqubo yokukhangela i-intanethi, ukubeka iliso kwangexesha lobungakanani bomsebenzi kunye neempazamo zemilo kwinkqubo yokucubungula, ukulungiswa ngexesha elifanelekileyo kwendawo yesixhobo okanye iiparitha zokucubungula ngokweziphumo zokubona, imbuyekezo yempazamo.

emva kokulungiswa

• Umlinganiselo ochanekileyo: Sebenzisa i-CMM, iprofayili kunye nezinye izixhobo zokulinganisa ngokuchanekileyo ukulinganisa ngokubanzi i-workpiece emva kokucubungula, ukufumana ubungakanani obuchanekileyo kunye nedatha yokuma, kunye nokubonelela ngesiseko sohlalutyo oluchanekileyo olulandelayo kunye nokulawula umgangatho.

• Uhlalutyo lwempazamo kunye nohlengahlengiso: Ngokweziphumo zokulinganisa, hlalutya izizathu zeempazamo ze-machining, ezifana nokugqoka izixhobo, ukuguqulwa kwamandla okusika, ukuguqulwa kwe-thermal, njl.

Ixesha lokuposa: Dec-20-2024