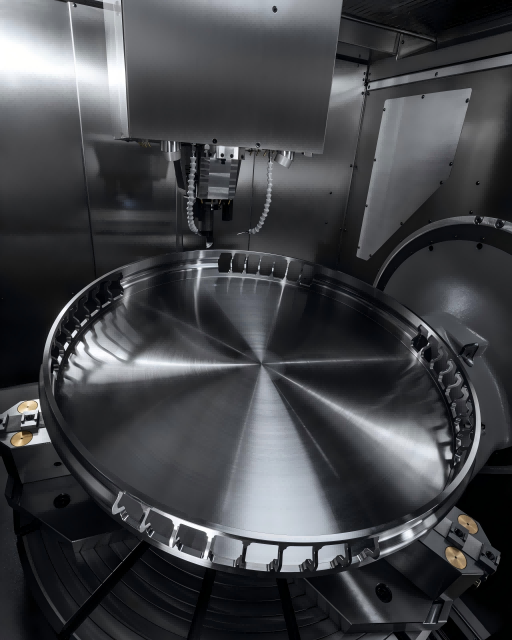

Izinto zensimbi ezingenasici zinzima ngokwentelekiso, emva koko ukwenza njani umatshini weCNC? CNC machining amacandelo steel stainless yinkqubo yokuvelisa eqhelekileyo, oku kulandelayo luhlalutyo yayo efanelekileyo:

Iimpawu zokucwangcisa

• Amandla aphezulu kunye nobunzima: izinto zensimbi ezingenasici zinamandla amakhulu kunye nobunzima, ukucubungula kufuna amandla amakhulu okusika kunye namandla, kwaye ukunxiba kwesixhobo kukhulu.

• Ukuqina kunye ne-viscosity: Ubunzima bensimbi engenasici bulungile, kwaye kulula ukuvelisa i-chip accumulation xa usika, echaphazela umgangatho wendawo yokucubungula, kwaye ibuye ibe ne-viscosity ethile, ekulula ukubangela ukuba ii-chips zijikeleze isixhobo.

• Ukungahambi kakuhle kwe-thermal: i-thermal conductivity iphantsi, kwaye ukushisa okwenziwa ngexesha lokucubungula akulula ukuchithwa, okulula ukubangela ukunyuka kwesixhobo kunye nokuguqulwa kwamalungu.

Itekhnoloji yokucubungula

• Ukukhethwa kwesixhobo: Izixhobo zezixhobo ezinobunzima obuphezulu, ukuxhathisa okulungileyo kunye nokumelana nokushisa okunamandla kufuneka kukhethwe, njengezixhobo ze-carbide ezifakwe ngesamente, izixhobo ezigqunyiweyo, njl.

• Iiparamitha zokusika: Iiparameters zokusika ezicacileyo zinceda ukuphucula ukusebenza komatshini kunye nomgangatho. Ngenxa yobunzima obunzulu bezinto zensimbi ezingenasici, ubunzulu bokusika akufanele bube bukhulu kakhulu, ngokubanzi phakathi kwe-0.5-2mm. Isixa sesondlo kufuneka sibephakathi ukunqanda isixa sesondlo esigqithisileyo esikhokelela ekwandeni kokunxitywa kwesixhobo kunye nokwehla komgangatho womphezulu wamalungu. Isantya sokusika sihlala siphantsi kuneso sentsimbi yekhabhoni eqhelekileyo yokunciphisa izixhobo zokusebenza.

• Ukupholisa i-lubrication: Xa kusetyenzwa iinxalenye zensimbi ezingenasici, kuyimfuneko ukusebenzisa inani elikhulu lokusika ulwelo lokuthambisa ukupholisa ukunciphisa ubushushu bokusika, ukunciphisa ukunxiba kwesixhobo, kunye nokuphucula umgangatho womgangatho womatshini. Ukusika ulwelo kunye neempawu ezintle zokupholisa kunye ne-lubricating zingakhethwa, njenge-emulsion, i-synthetic cutting fluid, njl.

Izinto eziyimfuneko zokucwangcisa

• Isicwangciso sendlela yesixhobo: Ngokwemilo yecandelo kunye neemfuno zokucubungula, ukucwangciswa okufanelekileyo kwendlela yesixhobo, ukunciphisa i-stroke engenanto kunye nokuguqulwa rhoqo kwesixhobo, ukuphucula ukusebenza kakuhle. Kwiindawo ezineemilo ezintsonkothileyo, itekhnoloji yokudibanisa i-multi-axis ingasetyenziselwa ukuphucula ukuchaneka kokulungiswa kunye nomgangatho womphezulu.

• Ukusetwa kwembuyekezo: Ngenxa yoguquko olukhulu lokusetyenzwa kwemathiriyeli yensimbi engenastainless, imbuyekezo yeradiyasi efanelekileyo yesixhobo kunye nembuyekezo yobude kufuneka isetwe ngexesha lenkqubo ukuqinisekisa ukuchaneka kobukhulu bezahlulo.

Ulawulo lwemeko

• Ulawulo lokuchaneka komgangatho: Ngexesha lenkqubo yomatshini, imilinganiselo yamacandelo kufuneka ilinganiswe rhoqo, kwaye iiparamitha zokucubungula kunye nembuyekezo yesixhobo kufuneka zilungiswe ngexesha ukuze kuqinisekiswe ukuba ukuchaneka kwe-dimensional kwamalungu kuyahlangabezana neemfuno.

• Ulawulo lobulunga bomphezulu: Ngokukhetha izixhobo ezifanelekileyo, iiparamitha zokusika kunye nolwelo lokusika, kunye nokwenziwa ngcono kweendlela zesixhobo kunye namanye amanyathelo, ukuphucula umgangatho wamalungu omphezulu, ukunciphisa uburhabaxa bomphezulu kunye nokuveliswa kwe-burr.

• Uncedo loxinzelelo: kusenokubakho uxinzelelo olushiyekileyo emva kokusetyenzwa kwamalungu entsimbi engenastainless, okukhokelela kuguquko okanye ukungazinzi komda kwezahlulo. Uxinzelelo olushiyekileyo lunokupheliswa ngonyango lobushushu, ukuguga kwe-vibration kunye nezinye iindlela.

Ixesha lokuposa: Dec-13-2024