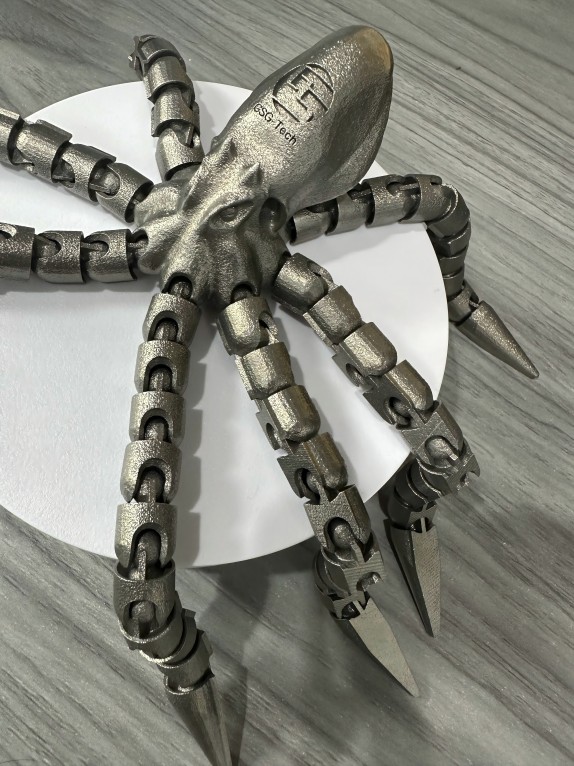

Kutshanje, senze umboniso wentsimbiUshicilelo lwe-3D, kwaye sayigqiba ngempumelelo kakhulu, ngoko yintoni isinyithiUshicilelo lwe-3D? Ziziphi iingenelo kunye nobubi bayo?

I-Metal 3D yoshicilelo yitekhnoloji eyongezelelweyo yokuvelisa eyakha izinto ezine-dimensional ezintathu ngokongeza i-metal materials layer by layer. Nantsi intshayelelo eneenkcukacha yoshicilelo lwesinyithi lwe-3D:

Umgaqo wobugcisa

I-laser sintering ekhethiweyo (SLS) : Ukusetyenziswa kwemiqadi ye-laser yamandla aphezulu ukunyibilika okukhethiweyo kunye ne-sinter powders yensimbi, ukufudumeza umgubo wezinto eziphathekayo kwiqondo lokushisa elingaphantsi kwendawo yokunyibilika kwayo, ukwenzela ukuba izibophelelo zetsimbi phakathi kwamasuntswana omgubo zenziwe, ngaloo ndlela zakha into yomaleko ngomaleko. Kwinkqubo yoshicilelo, umaleko ofanayo womgubo wentsimbi ubekwe kuqala kwiqonga lokushicilela, emva koko umqadi welaser uskena umgubo ngokwemilo enqamlezileyo yento, ukuze umgubo oskeniweyo unyibilike kwaye uqina kunye, emva kokugqitywa koluhlu lokushicilela, iqonga lehla umgama othile, kwaye emva koko kusasaze umaleko omtsha womgubo, phinda le nkqubo ingasentla ishicilelwe de yonke le nkqubo ishicilelwe.

Ukunyibilika kweLaser ekhethiweyo (SLM) : Ngokufana ne-SLS, kodwa ngamandla aphezulu e-laser, umgubo wesinyithi unokunyibilika ngokupheleleyo ukwenza ubume obuxineneyo, ukuxinana okuphezulu kunye neempawu ezingcono zoomatshini zinokufumaneka, kwaye amandla kunye nokuchaneka kweendawo zetsimbi eziprintiweyo ziphezulu, kufutshane okanye zigqithise iindawo eziveliswa yinkqubo yokwenziwa kwemveli. Ifanelekile kwiindawo zokuvelisa kwi-aerospace, izixhobo zonyango kunye nezinye iindawo ezifuna ukuchaneka okuphezulu kunye nokusebenza.

I-Electron beam melting (EBM) : Ukusetyenziswa kwemiqadi ye-electron njengomthombo wamandla wokunyibilikisa umgubo wesinyithi. Umqa we-electron uneempawu zokuxinana kwamandla aphezulu kunye nesantya esiphezulu sokuskena, esinokunyibilika ngokukhawuleza umgubo wesinyithi kunye nokuphucula ukusebenza kakuhle kokushicilela. Ukuprintwa kwindawo yokucoca kunokuphepha ukusabela kwezinto zetsimbi nge-oksijini ngexesha lenkqubo yokushicilela, efanelekileyo yokushicilela i-titanium alloy, i-alloy esekelwe kwi-nickel kunye nezinye izinto zetsimbi ezithintekayo kumxholo we-oksijini, ezidla ngokusetyenziswa kwi-aerospace, izixhobo zonyango kunye nezinye iindawo eziphezulu.

I-Metal material extrusion (ME) : Indlela yokuvelisa esekelwe kwi-Material extrusion, ngokusebenzisa intloko ye-extrusion ukuze ikhuphe izinto zetsimbi ngendlela yesilika okanye i-paste, kwaye ngexesha elifanayo ukufudumeza kunye nokunyanga, ukuze kuphunyezwe umaleko ngokubunjwa kokuqokelela. Xa kuthelekiswa neteknoloji yokunyibilika kwe-laser, iindleko zotyalo-mali ziphantsi, ziguquguquka ngakumbi kwaye zilungele, ngakumbi zilungele uphuhliso lwangethuba kwindawo yeofisi kunye nemeko yeshishini.

Izinto eziqhelekileyo

Ingxubevange ye-Titanium: ineengenelo zamandla aphezulu, ingxinano ephantsi, ukuxhathisa okulungileyo kokutya kunye nokuhambelana kwezinto eziphilayo, isetyenziswa ngokubanzi kwindawo yokubhabha, izixhobo zonyango, iimoto kunye namanye amabala, anje ngeencakuba zeinjini yenqwelomoya, amalungu angeyomfuneko kunye nezinye iindawo zokwenziwa.

Insimbi engagqwali: inokumelana ne-corrosion elungileyo, iipropathi zoomatshini kunye neepropathi zokusetyenzwa, ixabiso eliphantsi ngokwentelekiso, yenye yezinto ezisetyenziswa ngokuqhelekileyo kushicilelo lwentsimbi ye-3D, ingasetyenziselwa ukuvelisa iindawo ezahlukeneyo zoomatshini, izixhobo, izixhobo zonyango njalo njalo.

I-aluminium ingxubevange: ubuninzi obuphantsi, amandla aphezulu, ukuhanjiswa kakuhle kwe-thermal, ilungele iindawo zokuvelisa ezineemfuno eziphezulu zobunzima, njengebhloko ye-injini ye-cylinder block, i-aerospace yesakhiwo se-aerospace, njl.

I-alloy esekwe kwi-nickel: inamandla abalaseleyo obushushu obuphezulu, ukuxhathisa umhlwa kunye nokumelana ne-oxidation, ihlala isetyenziselwa ukwenziwa kwezinto zobushushu obuphezulu njengeenjini zenqwelomoya kunye nee turbines zegesi.

inzuzo

Iqondo eliphezulu lenkululeko yoyilo: Ukukwazi ukufezekisa ukuveliswa kweemilo eziyinkimbinkimbi kunye nezakhiwo, ezifana nezakhiwo ze-lattice, izakhiwo eziphuculweyo ze-topologically, njl., ezinzima okanye ezingenakwenzeka ukufezekiswa kwiinkqubo zokuvelisa zemveli, zibonelela ngeendawo ezintsha ezintsha zoyilo lwemveliso, kwaye zinokuvelisa ukukhanya, iindawo eziphezulu zokusebenza.

Ukunciphisa inani leenxalenye: iindawo ezininzi zinokudibaniswa ngokupheleleyo, ukunciphisa uxhulumaniso kunye nenkqubo yokuhlanganisana phakathi kwamacandelo, ukuphucula ukusebenza kwemveliso, ukunciphisa iindleko, kodwa nokuphucula ukuthembeka nokuzinza kwemveliso.

Iprototyping ekhawulezileyo: Inokuvelisa iprototype yemveliso ngexesha elifutshane, ikhawulezise umjikelo wophuhliso lwemveliso, inciphise iindleko zophando kunye nophuhliso, kwaye incede amashishini azise iimveliso kwintengiso ngokukhawuleza.

Imveliso eyenziwe ngokwezifiso: Ngokweemfuno zomntu ngamnye zabathengi, iimveliso ezizodwa zinokwenziwa ukuze zihlangabezane neemfuno ezikhethekileyo zabathengi abahlukeneyo, ezifanelekileyo ukufakelwa kwezonyango, ubucwebe kunye nezinye iindawo ezilungiselelwe.

Ukulinganiselwa

Umgangatho ophantsi womgangatho ophantsi: Ubunzima bomphezulu weendawo zetsimbi eziprintiweyo ziphezulu, kwaye emva kokunyanga kuyadingeka, njengokugaya, ukupholisa, ukuchithwa kwesanti, njl., Ukuphucula ukugqitywa kwendawo, ukwandisa iindleko zokuvelisa kunye nexesha.

Iziphene zangaphakathi: kunokubakho iziphene zangaphakathi ezifana ne-pores, iinqununu ezingaxutywanga, kunye nokudibanisa okungaphelelanga ngexesha lenkqubo yokushicilela, echaphazela iimpawu zemishini yamacandelo, ngokukodwa ekusebenziseni umthwalo ophezulu kunye nomthwalo we-cyclic, kuyimfuneko ukunciphisa ukwenzeka kweziphene zangaphakathi ngokulungiselela iiparameters zenkqubo yokushicilela kunye nokwamkela iindlela ezifanelekileyo ze-post-processing.

Unyino lwezinto eziphathekayo: Nangona iindidi zentsimbi ye-3D yoshicilelo lwezixhobo ezikhoyo zisanda, kusekho imida ethile yezinto eziphathekayo xa kuthelekiswa neendlela zokuvelisa zendabuko, kwaye ezinye izinto zetsimbi ezisebenza kakhulu zinzima kakhulu ukuprinta kwaye iindleko ziphezulu.

Imiba yeendleko: Ixabiso lezixhobo zoshicilelo zetsimbi ze-3D kunye nezixhobo ziphezulu kwaye isantya sokushicilela sicotha, esingabizi kakhulu njengeenkqubo zokuvelisa zemveli zemveliso enkulu, kwaye okwangoku ifanelekile kakhulu kwibhetshi encinci, imveliso eyenziwe ngokwezifiso kunye neendawo ezinemveliso ephezulu yokusebenza kunye neemfuno zomgangatho.

Ubunzima bobugcisa: Ukushicilelwa kwe-Metal 3D kubandakanya iiparameters zenkqubo enzima kunye nokulawulwa kwenkqubo, efuna abaqhubi beengcali kunye nenkxaso yobugcisa, kwaye ifuna inqanaba eliphezulu lobugcisa kunye namava abaqhubi.

Indawo yosetyenziso

I-Aerospace: Isetyenziselwa ukwenza ii-aero-injini ze-aero-injini, ii-discs ze-turbine, izakhiwo zamaphiko, iinxalenye zesathelayithi, njl., ezinokunciphisa ubunzima beengxenye, ukuphucula ukusebenza kakuhle kwamafutha, ukunciphisa iindleko zokuvelisa, kunye nokuqinisekisa ukusebenza okuphezulu kunye nokuthembeka kwamacandelo.

Imoto: Yenza ibhlokhi ye-injini yemoto, iqokobhe lokuhambisa, iinxalenye zesakhiwo esikhaphukhaphu, njl., ukufezekisa uyilo olukhaphukhaphu lweemoto, ukuphucula uqoqosho lwamafutha kunye nokusebenza.

Unyango: Ukuveliswa kwezixhobo zonyango, amalungu okufakelwa, i-orthotics yamazinyo, izixhobo zonyango ezifakelweyo, njl.

Imveliso yokungunda: Ukuvelisa imifuziselo yesitofu, i-mold casting molds, njl., ukunciphisa umjikelo wokuvelisa i-mold, ukunciphisa iindleko, ukuphucula ukuchaneka kunye nobunzima bokubumba.

I-Electronics: Yenza iiradiyetha, iigobolondo, iibhodi zeesekethe zezixhobo ze-elektroniki, njl., ukuphumeza ukuveliswa okuhlangeneyo kwezakhiwo ezinzima, ukuphucula ukusebenza kunye nefuthe lokutshatyalaliswa kobushushu bezixhobo zombane.

Ubucwebe: Ngokobuchule bomyili kunye neemfuno zabathengi, iintlobo ngeentlobo zobucwebe obukhethekileyo zinokuveliswa ukuphucula ukusebenza kakuhle kwemveliso kunye nokwenziwa kwemveliso.

Ixesha lokuposa: Nov-22-2024