Kutshanje senze ibhetshi encinciCNC ngoomatshini iindawo isiko. Kwinkqubo ye-batch processing, siqinisekisa njani ukuchaneka kwebhetshi yonke yamacandelo?Kwimveliso yobuninzi beengxenye ze-CNC, ukuqinisekisa ukusebenza kakuhle kunye nokuchaneka kunokuqala kule miba ilandelayo.

Ukusebenza kakuhle, eyokuqala yinkqubo efanelekileyo.

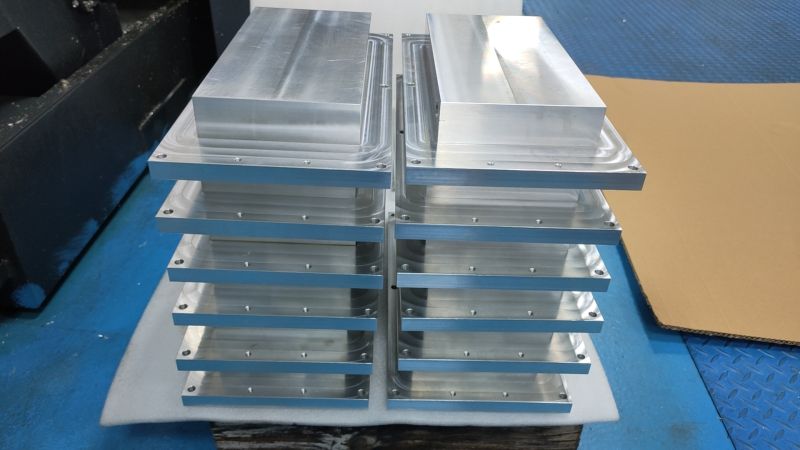

Indlela yesixhobo iphuculwe ngexesha lokucwangcisa ukunciphisa ukuhamba okungenanto kunye nezenzo zokusika ezingadingekile, ukwenzela ukuba isixhobo sinokucutshungulwa ngokukhawuleza nangendlela echanekileyo. Ngokomzekelo, xa iindawo zokugaya, iindlela ezisebenzayo zokugaya, ezifana nokugaya iindlela ezimbini, kunokunciphisa ixesha lokuhamba kwesixhobo ngaphandle kwendawo yokucubungula. Okwesibini kukukhethwa kwezixhobo. Ngokwenxalenye yemathiriyeli kunye neemfuno zomatshini, khetha isixhobo esifanelekileyo kunye nohlobo lwesixhobo. Ngokomzekelo, xa kusetyenzwa iinxalenye ze-aluminium alloy, ukusetyenziswa kwezixhobo zetsimbi ezikhawulezayo kunokuphucula isantya sokusika, ngaloo ndlela kuphuculwe ukusebenza kakuhle. Ngaphezu koko, kuyimfuneko ukuqinisekisa ubomi benkonzo yesixhobo, endaweni yesixhobo esigugileyo ngexesha, kwaye ugweme ukuncipha kwesantya sokucutshungulwa ngenxa yokunxiba isixhobo. Ukongeza, ulungiselelo olufanelekileyo lweenkqubo zokucubungula lubaluleke kakhulu. Beka embindini uhlobo olufanayo lokucubungula ukunciphisa inani lamaxesha okubamba, umzekelo, yonke imisebenzi yokugaya inokwenziwa kuqala, kwaye emva koko imisebenzi yokomba. Ngexesha elifanayo, ukusetyenziswa kokulayishwa ngokuzenzekelayo kunye nokukhulula isixhobo kunokunciphisa ixesha lokulayisha ngesandla kunye nokukhupha, ukufezekisa ukuqhutyelwa okungaphazamisekiyo kwesixhobo somatshini, kunye nokuphucula ukusebenza kakuhle.

Kwinkalo yokuqinisekiswa kokuchaneka, ukugcinwa ngokuchanekileyo kwezixhobo zoomatshini ngundoqo.

Kuyimfuneko ukujonga kunye nokulinganisa isixhobo somatshini rhoqo, kubandakanywa ukuchaneka kokumisa ii-axes zokulungelelanisa kunye nokuphindaphinda ukuchaneka kokumisa. Ngokomzekelo, i-interferometer ye-laser isetyenziselwa ukulinganisa i-axis yesixhobo somatshini ukuqinisekisa ukuchaneka kwentshukumo yesixhobo somatshini. Kwaye ukuzinza kwe-clamping kubaluleke kakhulu, khetha ukulungiswa okufanelekileyo ukuqinisekisa ukuba iindawo aziyi kususwa ngexesha lokucubungula. Ngokomzekelo, xa ucubungula iindawo ze-shaft, ukusetyenziswa kwe-three-jaw chuck kunye nokuqinisekisa ukuba i-clamping force yayo ifanelekile inokuthintela ngokufanelekileyo iindawo ezivela kwi-radial runout ngexesha lokujikeleza. Ukongeza, ukuchaneka kwesixhobo akunakunakwa. Sebenzisa izixhobo ezichanekileyo eziphezulu, kwaye uqinisekise ukuchaneka kofakelo xa isixhobo sifakwe, njengaxa ufaka i-drill, ukuqinisekisa i-coaxial degree ye-drill kunye ne-spindle machine. Ukongeza, imbuyekezo ngexesha lokucubungula nayo iyimfuneko. Inkqubo yokulinganisa ibeka esweni ubungakanani bomatshini bamacandelo ngexesha langempela, kwaye emva koko ihlawule impazamo yomatshini kunye nomsebenzi wembuyekezo wenkqubo ye-CNC ukuqinisekisa ukuchaneka kwe-dimensional yamacandelo.

Ixesha lokuposa: Dec-27-2024