Icandelo lemveliso liphakathi kwawona mashishini aguqukayo. Namhlanje, kukho i-push engapheliyo yokuphucula ukuchaneka okupheleleyo kunye nokuchaneka kunye neenkqubo ezifana ne-EDM yocingo ehambisa ngokuchanekileyo engeyonto emfutshane yokuguqula ishishini.

Ngoko ke, yintoni i-Wire EDM ngokuchanekileyo, kwaye kutheni ithathwa njengokutshintsha umdlalo kwicandelo lokuvelisa? Isicatshulwa esilandelayo siya kujonga kwiziseko zobu buchule bokwenza obuphucukileyo kunye nokusetyenziswa kumashishini ahlukeneyo.

Isingeniso esifutshane kwi-EDM yocingo

I-Wire Electrical Discharge Machining (EDM) yaba nguvulindlela kwi-1940 ngoososayensi ababini baseSoviet abaqala ukutshabalalisa isinyithi ngokukhutshwa kombane. Itekhnoloji ibone ukuqhubela phambili okubonakalayo kwiminyaka yama-60s kunye ne-80s, isiya ixhaphake kakhulu kurhwebo kwimveliso. Ngasekupheleni kweminyaka engama-90, kunye nokuphuculwa kwe-IT kunye ne-CNC, oomatshini bocingo be-EDM baba nekhompyuter ngakumbi, bonyusa ukusebenza kwabo kunye nokuchaneka.

Namhlanje, i-Wire EDM ibalulekile kumashishini afana ne-Aerospace, i-Automotive, kunye ne-Medical, eyaziwayo ngokuhambisa uyilo oluntsonkothileyo kunye neefom ezintsonkothileyo ezingahambelaniyo neendlela zemveli zokwenza.

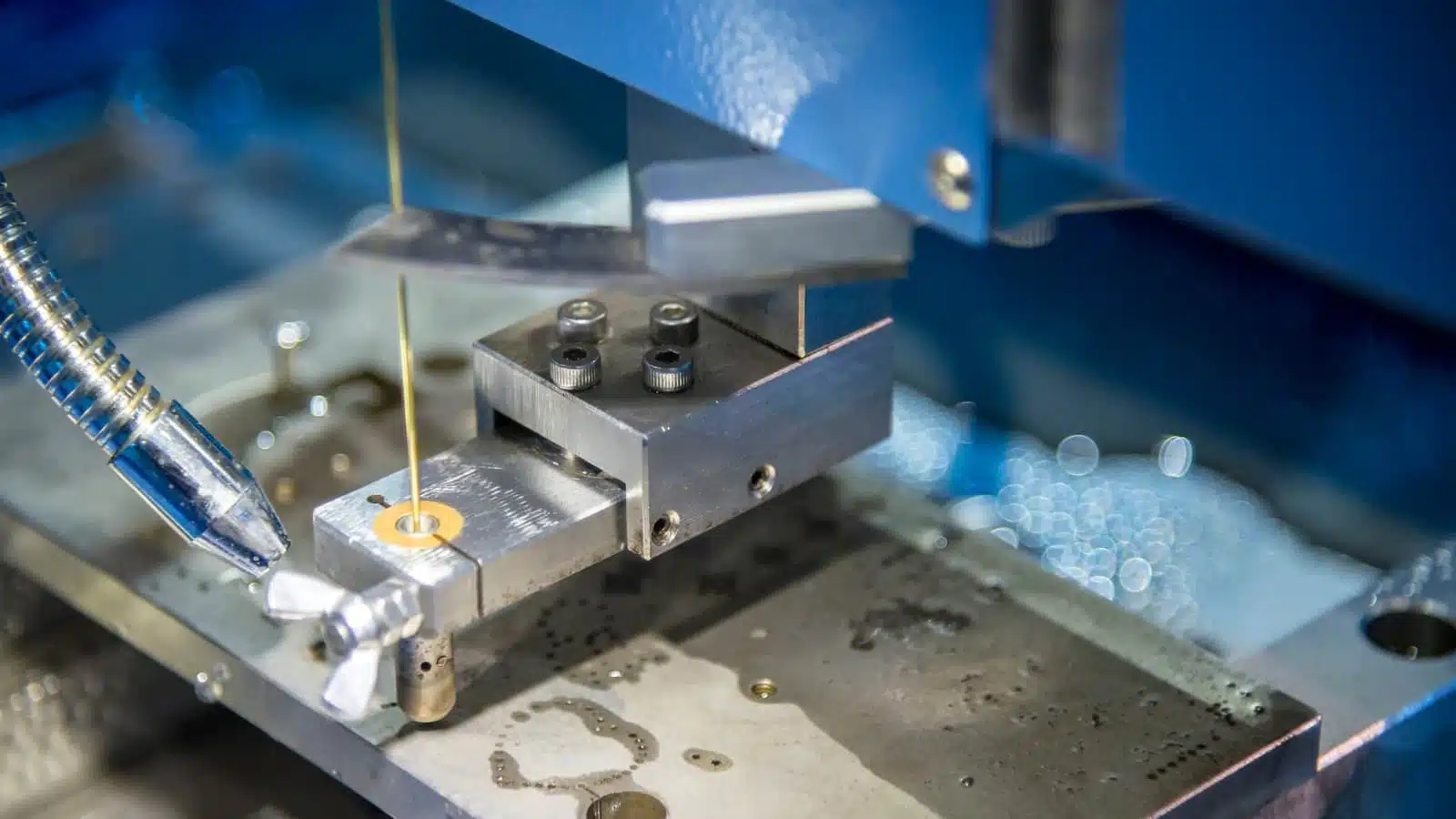

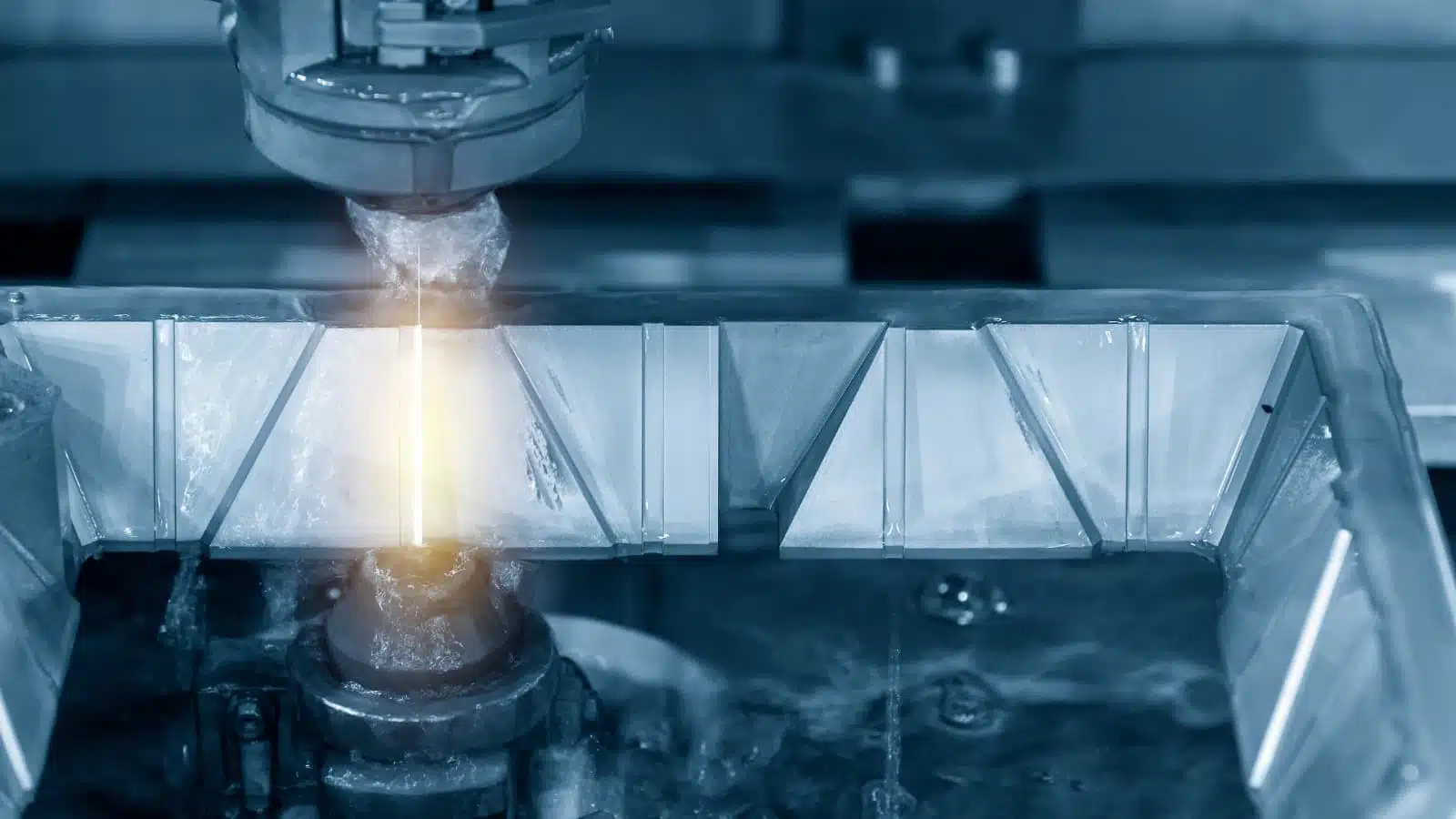

Inkqubo ye-EDM yocingo

I-Wire Electrical Discharge Machining (EDM) yindlela echanekileyo esebenzisa iintlantsi zombane ezilawulwayo ukunyibilikisa iindawo ezincinci zomsebenzi. I-electrode yocingo, ngokuqhelekileyo eyenziwe ngobhedu okanye i-zinc-coated materials, idala le ntlantsi kwaye ihambe ngendlela ebekwe ngaphambili. Inzuzo yayo? Isebenza ngaphandle kokudibana ngokomzimba, ukuthintela nawuphi na umonakalo okanye amanqaku kuzo zombini i-workpiece kunye nesixhobo.

I-EDM isebenza njani

I-EDM ixhomekeke kumandla obushushu ukusuka ekuphumeni kombane. Oku kukhutshwa kutshisa i-workpiece ukuya kwindawo yayo yokunyibilika, yenze imijelo emincinci yeplasma. La majelo, adla ngokulingana nemicrometer, anokuphela ngokukhawuleza.

Inkqubo ye-EDM yenzeka kwi-dielectric medium, ngokuqhelekileyo amanzi adibeneyo. Olu lwelo lupholisa i-workpiece kwaye lususe imathiriyeli engumphunga, inceda kumatshini oqhubekayo.

Ukubaluleka kwe-Electrode yocingo

Ukusebenza njenge-cutter kunye ne-conductor, i-electrode yocingo ibalulekile. Igqutywe ngezinto ezifana nobhedu okanye i-zinc, iyamelana neempendulo kumaqondo obushushu aphezulu. Ukulawulwa yikhompyuter, iqinisekisa ukusikwa okuchanekileyo kunye nokuphazamiseka okuncinci kunye nokuchaneka okuphezulu.

Ukunyamezela kwi-EDM yocingo

Ukusika ucingo kuphakathi kwezona nkqubo zichanekileyo zokuvelisa. Ke, ukunyamezelana okuqinileyo akunto ingaqhelekanga kuyo. Olona nyamezelo luxhomekeke kwizinto ezininzi ezibandakanya ubucukubhede beprojekthi, ubuchule bokusebenza, kunye nezakhono zomqhubi.

Nangona kunjalo, umgangatho kunye nonyamezelo olwamkelekileyo luphawu loshishino olulandelwa ngabakhiqizi abaninzi.

Ukunyamezelana okuMgangatho kunye noNyamezelo oluLungileyo

Ukunyamezelana okusemgangathweni

Ukunyamezelwa komgca: Ngokuqhelekileyo ukusuka kwi-± 0.005 ukuya kwi-± 0.001 intshi (0.127 ukuya kwi-0.0254 mm), ebonisa ukutenxa okuvumelekileyo kwiimpawu ezifana nemingxuma, iindawo zokubeka, okanye iiprofayili.

Ukunyamezela kwe-Diameter ye-Hole: Ngokuqhelekileyo phakathi kwe-± 0.0005 ukuya kwi-± 0.001 intshi (0.0127 ukuya kwi-0.0254 mm), ukuqinisekisa ukuba imingxuma ematshini ihlala ngaphakathi kobubanzi obuchaziweyo.

Ukunyamezelana

Ukunyamezelwa komgca: Ukuphumeza ukuchaneka kwinqanaba le-micron, ngokuqhelekileyo ukusuka ku-±0.0002 ukuya kwi-±0.0001 intshi (0.0051 ukuya kwi-0.00254 mm), ibalulekile kwizicelo ezifuna ukuchaneka okukhulu.

Ukunyamezela kwe-Diameter ye-Hole: Iindidi ukusuka kwi-± 0.0001 ukuya kwi-± 0.00005 intshi (0.00254 ukuya kwi-0.00127 mm), igxininisa ukuchaneka okukhethekileyo kwe-Wire EDM.

Izinto ezichaphazela ukunyamezela kwi-Wire EDM

I-EDM yocingo idume ngokuchaneka kwenqanaba le-micron, iyenza ilungele izicelo ezintsonkothileyo. Nangona kunjalo, ukuchaneka kwayo akulungiswanga kwaye kuxhomekeke kwizinto ezininzi:

• Ukuzinza komatshini: Umatshini ozinzile uqinisekisa ukuchaneka okungcono kwizenzo zokusika.

• Umgangatho wocingo kunye nobubanzi: Ukucoceka kwayo, i-diameter, kunye neempawu zombane zinefuthe kwinkqubo yomatshini. Iziphumo ezizezona zifuna ukulingana phakathi komgangatho wocingo kunye nedayamitha.

•IMaterial yoMsebenzi: Ngelixa ezinye imathiriyeli zifikeleleka ngakumbi koomatshini, ukhetho lwemathiriyeli kufuneka luhambelane neemfuno zesicelo.

• Iimeko ze-Flush: Ukuhamba kwe-dielectric medium, kuchaphazela umgangatho wenkqubo ye-machining, i-aids ekususeni izinto eziphathekayo, ukukhutshwa kombane okuhambelanayo, kunye nokutshatyalaliswa kobushushu obusebenzayo.

•Ulungelelwaniso lomatshini kunye noLondolozo: Izakhono zoomatshini zibalulekile. Oomatshini abaphezulu abanabasebenzi abanobuchule bayimfuneko ekuphumezeni okona kunyamezelwayo.

• Ukuzinza kweThermal: Ukugcina ukuchaneka okwaziwayo kwe-Wire EDM, ii-arcs zombane ezilawulwayo zibalulekile. Ukungazinzi kwe-thermal kunokuphazamisa ukuchaneka, kugxininisa ukubaluleka kweemeko ezihambelanayo.

Ezona zixhobo ziFanelekileyo zokusika ucingo

Iintsimbi zentsimbi

Yenziwe ngentsimbi eshayinayo

Idibanisa ukuqina kunye ne-conductivity egqwesileyo yombane. Ukukwazi kwayo ukuxhathisa umhlwa kuyenza ibe yinto efunwayo kumashishini ahlukeneyo. Kumxholo womatshini, ukuhambelana kwayo kunye noyilo oluchanekileyo kunye neenkcukacha luvelele.

Isixhobo sentsimbi

Eyaziwayo ngeempawu zayo ezilukhuni, insimbi yesixhobo ngumqolo wezixhobo ezininzi ezinzima kunye neengxenye ezichanekileyo. Ukuqina kwayo okungokwemvelo, xa kudityaniswa neempawu zayo zombane, kuyenza ibe ngumgqatswa ophambili kwiinkcukacha ezintsonkothileyo kunye nobubukhali obuhlala ixesha elide.

Intsimbi yeCarbon

Umdlali oguquguqukayo kwi-domain yensimbi, i-carbon steel, nangona ingaphantsi kwe-machable kunezakwabo, inokulungelelaniswa ngokugqibeleleyo kunye nokukhetha okulungileyo kwe-electrode kunye neeparitha zokusebenza. Ukufikeleleka kwayo kudityaniswe nokusebenza kwayo kuyenza ibe yeyona nto iphambili kumashishini amaninzi.

Intsimbi yentsimbi

Ukudityaniswa kwezinto, ukusebenza kwentsimbi ye-alloy yi-tapestry yamacandelo ayo. Ngokuxhomekeke kumdibaniso wayo okhethekileyo, inokunika amandla, ukuqina, kunye nobuchule, iyenze ibe lukhetho oluguquguqukayo kwizicelo ezahlukeneyo.

Iintsimbi ezingezizo ezoNyore

I-Titanium

Idla ngokubizwa ngokuba 'yintsimbi yexesha elide', ukomelela kwe-titanium kunye nendawo yokunyibilika ephezulu kubangela imiceli-mngeni kumatshini oqhelekileyo. Nangona kunjalo, xa icocwe ngezixhobo ezichanekileyo, ityhila uyilo oluntsonkothileyo nolomeleleyo, nto leyo eyenza ibe yeyona nto ithandwayo kwi-aerospace kunye nemizi-mveliso yezonyango.

Aluminiyam

Intanda yesinyithi esikhaphukhaphu, ialuminiyam ibhiyozelwa ngokusebenza kwayo kombane okugqwesileyo kunye nokuguquguquka. Ayinikezeli ngokulula komatshini kodwa ikwathembisa amandla ngaphandle komthwalo wobunzima, iyenza ibe ngundoqo kumashishini ukusuka kwezothutho ukuya ekupakishweni.

Ubhedu

I-conductor egqwesileyo, ubhedu lusembindini wemimangaliso emininzi yombane neye-elektroniki. I-hue yayo yendalo ebomvu-orenji idityaniswe nobuchule bayo bokubumba kwizinto ezineenkcukacha yenza ukuba ibaluleke kakhulu kuyo yonke into ukusuka kwi-electronics ukuya kubugcisa bokuhombisa.

Ubhedu kunye noBronze

Ezi alloys, ezikhazimlayo kwiitoni zazo zegolide, azikho nje malunga ne-aesthetics. Iimpawu zabo zombane ezincomekayo zibenza baye kwizinto zokwenziwa kwezinto apho ukuchaneka kuhlangana nobuhle, njengakwizacholo ezihonjisiweyo okanye iinxalenye ze-elektroniki ezenziwe kakuhle.

Izicelo eziphambili ze-EDM yocingo kubuNjineli banamhlanje

I-Wire EDM machining ifumana i-traction ngenxa yokuguquguquka kwayo ekuphatheni izinto ezahlukeneyo kunye nokukwazi kwayo ukufezekisa iinkcukacha ezichanekileyo kunye nokunyamezela okuqinileyo, okwenza kube yinto ebalulekileyo kwimveliso yanamhlanje. Nazi izicelo ezintathu eziphambili:

Ukwenziwa kwezahlulo ezichanekileyo

Ukhetho oluqhelekileyo lokuvelisa iindawo ezichanekileyo eziphezulu kunye nokunyamezela okuqinileyo. Iyagqwesa ekuveliseni iimilo ezintsonkothileyo, iinkcukacha ezintle, kunye neempawu ezincinci kwizinto ezahlukeneyo.

Amashishini afana ne-aerospace, unyango, i-automotive, kunye ne-electronics ixhomekeke kwi-Wire EDM ukwenza izinto ezibalulekileyo njengeegiya, ii-nozzles, i-connectors, kunye ne-molds eyinkimbinkimbi.

Isixhobo kunye nemveliso yokufa

I-EDM yocingo iluncedo ekwenzeni i-molds, i-dies, kunye nezixhobo ezikhethekileyo, ukulungiselela iinkqubo ukusuka ekubunjweni kwenaliti ukuya kwi-stamping. Ubuchule bendlela yokuxhasa imilinganiselo echanekileyo kunye nokukrola ii-engile ezibukhali kuqinisekisa umgangatho we-premium kunye nokufana kwimveliso enkulu.

Uphuhliso lwePrototype

Ukwenziwa kweprototyping ekhawulezayo nangokuchanekileyo, iinjineli kunye nabavelisi batsalela kwi-Wire EDM. Oku kukhawuleza ukuqinisekiswa koyilo kunye nezigaba zovavanyo olungqongqo.

Iiprototypes ezichotshoziweyo nge-Wire EDM ngokusondeleyo zizibuko imveliso yokugqibela, iqinisa ukubaluleka kwayo kumjikelo wokuzivelela kwemveliso.

Ngenxa yamandla ayo kwezi ndawo zingundoqo, i-Wire EDM's ichanekileyo kunye nezakhono ezichanekileyo zixhaswe ngokubanzi kumashishini amaninzi.

•Ukwenziwa kweZixhobo zoNyango

•I-Electronics kunye neMicro-components

•I-Aerospace kunye ne-Aviation

•Izacholo kunye nokwenza iiwotshi

•Ushishino lweemoto

•ICandelo lezaMandla

•Ukulungisa uMngundo kunye nokufa

Ixesha lokuposa: Dec-12-2023